Aluminum U bars (U-channels) in 2025 are most commonly made from 6xxx-series alloys (especially 6063 and 6061) and are produced to ASTM/EN extrusion tolerances. Market pricing in 2025 varies strongly by region and order type: raw Chinese factory extrusion prices (FOB, bulk) typically sit in the ~USD 1.9–3.8 / kg band for standard profiles, while finished/retail U-channel products in the U.S. and Europe commonly sell at tens of USD per metre because of cutting, anodizing, inventory and dealer margins. Global primary aluminium commodity levels remain the largest single driver of cost.

1. What is an Aluminum U bar (U-channel)?

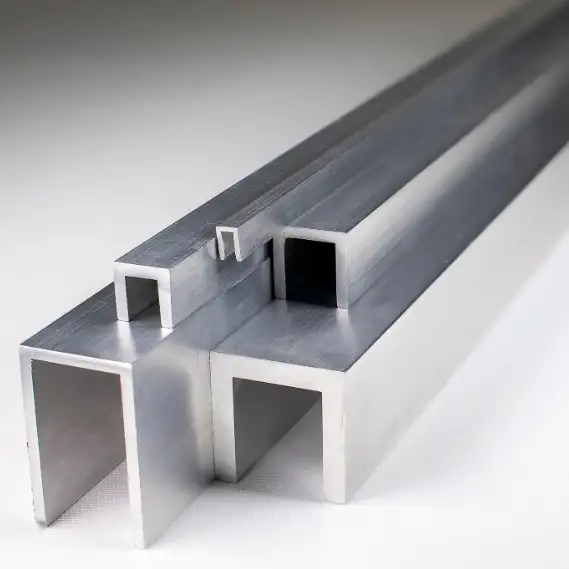

An Aluminum U bar — also called a U-channel, C-channel (in some catalogs), or U-profile — is an extruded profile with two parallel “legs” and a web forming a “U” cross-section. It is widely used in architectural trim, framing, LED channels, machine guards, edge protection, and structural framing where light weight and corrosion resistance are required.

2. Typical alloys and tempers used in U bars

For extruded U-channels the 6000 series dominates:

-

6063 (most common for architectural and general extrusion): excellent surface finish, anodizing quality and good extrudability.

-

6061 (stronger than 6063; used where mechanical strength is required).

-

For heavy structural or marine use, alloys like 6082 / 6005 / 6082 appear in Europe.

Tempering (T5, T6, T52 etc.) is chosen based on required strength vs. finish.

3. Applicable standards and tolerances

Extrusions are normally produced to recognized standards:

-

ASTM B221 — Standard for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes (North America). This is the primary spec for extruded profiles.

-

EN 755 (parts) — European series specifying tolerances on extruded profiles and dimensions. Use EN 755-9 / EN 755-1 for profile tolerances and form.

We always request a copy of the vendor’s mill certificate (material grade + temper) and dimensional inspection report for engineering work.

4. Common sizes and how dimensions are specified

Sizes are usually offered in imperial (in) and metric (mm). A sample of common U-channel cross-sections (as sold by suppliers) includes:

-

3/4″ × 1-1/2″ × 1/8″ (roughly 19 × 38 × 3 mm) — common for trim/LED channels.

-

2″ × 1″ × 1/8″ (approx 50 × 25 × 3 mm) — common general purpose channel.

-

2″ × 2″ × 1/8″ — heavier section for small structural applications.

Dimension notation typically lists leg height × web width × wall thickness. Ordering should specify alloy, temper, finish and length tolerances.

5. How to calculate weight per metre

Use the catalogue weight if supplied. If you need to compute: convert cross-sectional area (mm²) × density (aluminium ≈ 2.70 g/cm³ or 2700 kg/m³) to get kg/m. As a practical check, many supplier tables list lb/ft; convert lb/ft to kg/m with factor:

-

1 lb/ft ≈ 1.48816 kg/m.

Example: a channel listed as 0.49 lb/ft ≈ 0.49 × 1.48816 ≈ 0.73 kg/m. (This matches supplier weight tables).

6. Manufacturing and finishing options

Common finishes and secondary operations:

-

Mill finish (raw extrusion)

-

Anodized (architectural, corrosion resistance, color)

-

Powder coat (color & protection)

-

Machining, punching, cutting to length, drilling — typical from factories like ours

-

Packaging & kitting for just-in-time delivery

Anodizing usually adds cost and lead time but increases value for architectural uses.

7. Mechanical properties & design considerations

-

Use 6061 for higher loads; 6063 for trim and aesthetic uses. Compare yield and tensile numbers from material datasheets when designing.

-

Account for lateral torsional buckling in long slender U profiles and ensure adequate stiffening/fastening intervals.

-

Consider notch sensitivity if machining or cold-forming; corners may require fillets per EN/ASTM tolerances.

8. Typical 2025 price drivers

The main cost inputs in 2025:

-

Primary aluminium price (LME & other exchanges) — still the dominant driver. Market forecasts and volatility in 2025 have been referenced across broker and analyst reports.

-

Energy and smelting costs, local policy (tariffs), logistics and freight — these can shift regional final prices materially. News and analyst variation in 2025 highlight that commodity outlook changed through the year.

-

Alloy and temper selection, secondary processing (anodize, cut-to-length) — add to factory extrusion cost.

-

Order quantity and length (small cuts raise unit cost) — typical in any extrusion business.

9. 2025 global price comparison — examples and estimates

Notes on methodology: we surveyed supplier catalogues, Chinese factory price listings, and market reports (sampled suppliers and market platforms). The table shows representative items and typical price bands in mid-2025 — use it as a procurement starting point. Sources include MetalsDepot / OnlineMetals (US retail), Made-in-China / Alibaba and Chinese extruders (factory prices), and Shanghai/commodity price reports.

| Example U-Channel (cross-section) | Weight (lb/ft) (supplier) | kg/m (calc) | China factory (bulk) USD/kg range (2025) | China factory est. USD / m (example) | US retail approx USD / m (catalog sample) |

|---|---|---|---|---|---|

| 1½″ × 1″ × 1/8″ (≈38×25×3mm) | 0.49 lb/ft. | 0.73 kg/m (calc) | $1.9–3.5 / kg (typical Chinese extrusion ranges). | ~$1.4 – $2.6 / m (0.73×$1.9 → 0.73×$3.5) | ~$30–$40 / m (retailer example: $10.72 / ft → $35.2 / m). |

| 2″ × 1″ × 1/8″ | 0.56 lb/ft. | 0.83 kg/m | $1.9–3.8 / kg (range) | ~$1.6 – $3.2 / m | ~$35–$60 / m (depending on length/finish). |

| 2″ × 2″ × 1/8″ | 1.00 lb/ft. | 1.48 kg/m | $1.9–3.8 / kg | ~$2.8 – $5.6 / m | ~$60–$100 / m (heavier section, stocked lengths). |

Commodity context: analysts’ and exchange data in 2025 show LME primary aluminium trading in the few thousand USD per tonne range and forecasts have varied through the year (examples: analyst poll averages near $2,500/mt; some bank forecasts mid-$2,000/mt for parts of 2025). These commodity swings change mill billet cost and therefore extrusion base cost.

Interpretation: the raw factory cost per metre (China, bulk) can be very low — often a few dollars per metre for small to medium U-channels — because base metal cost is spread over the kg of metal. By the time material moves through cutting, anodizing, inspection, dealer margins and international freight, final retail prices in the US/EU can be an order of magnitude higher.

10. How to buy: factory vs distributor — tips to save cost

-

For large orders (tons) buy direct from an extrusion factory (FOB China) — you leverage factory prices, custom tooling amortization and faster lead times for stocked alloys. We (Luokaiwei) provide tooling, small MOQ options for custom sections, and fast stock delivery for standard items.

-

For small quantities or immediate needs, a local distributor or online reseller (Onlinemetals, MetalsDepot) is faster but pricier — expect cutting/packaging/overhead premiums.

-

Ask for detailed price build-up (billet cost, extrusion per kg, finishing, packing) — this helps identify savings.

-

Negotiate payment and logistics (EXW vs FOB vs CIF) to control freight/insurance cost.

11. Luokaiwei manufacture and service advantages (what we offer)

We operate as an integrated manufacturer in China supplying global buyers. Our advantages:

-

100% factory price advantage: because we are a producer, not a reseller, we quote close to mill-level extrusion costs for bulk orders.

-

Custom tooling & design support: we can open dies for new U-profiles and optimize wall thickness to save weight without losing strength.

-

Fast delivery for stocked items: standard sizes in 6063/6061 are available from our stock program for rapid shipment.

-

Quality & traceability: mill certificates, dimensional inspection reports and third-party testing available on request.

-

Secondary services: anodizing, cutting, CNC punching, and assembly for turnkey supply.

If you want sample pricing for a specific size, alloy and finish, tell us quantity, length and finish — we’ll provide factory FOB and CIF quotes.

12. FAQs

Q1 — Which alloy should I choose for a load-bearing U-channel?

A: Choose 6061-T6 when higher yield strength is required; choose 6063-T5/T52 when surface finish, anodizing and extrusion quality are priorities. For marine or very heavy duty, consider 6005 / 6082 as appropriate.

Q2 — How much does anodizing add to cost and lead time?

A: Anodizing adds both cost (typically several hundred dollars per batch depending on quantity and size) and a few days of processing. Price per metre depends on batch size, dye color, and surface prep. Always get anodize quotes separately.

Q3 — Can U-channels be cut to custom lengths and supplied with holes?

A: Yes. Most extrusion factories (including us) offer cut-to-length, drilling/punching, and assembly. Small-quantity cutting will add per-piece handling costs.

Q4 — Do you ship sample pieces?

A: Yes. We ship small samples via courier. For new dies we usually supply free prototype samples for qualification (subject to negotiation).

Q5 — Where should I benchmark prices?

A: Benchmark both (a) local distributor retail for immediate delivery (catalog prices e.g., Onlinemetals/MetalsDepot) and (b) factory FOB quotes from Chinese extruders for bulk orders (Made-in-China / Alibaba samples). Compare on kg/m basis and include finishing + freight.

13. Appendix — example conversions & calculations

-

Convert lb/ft → kg/m: multiply by 1.48816.

-

Example: 0.49 lb/ft × 1.48816 ≈ 0.73 kg/m. (Used in table above.)

How we compiled this report

We reviewed supplier catalogues and market sources in order to synthesize practical procurement guidance: product pages (MetalsDepot, OnlineMetals), Chinese factory listings (Made-in-China, Alibaba), extrusion cost commentary, and market/commodity reporting (LME, Reuters, Shanghai Metal). We used ASTM and EN standard references for tolerances and material selection. This lets us fill gaps that single supplier pages often omit (e.g., how commodity price changes affect factory vs retail margins). Representative sources used are cited throughout this document.

Actionable next steps (if you’re sourcing)

-

Send your exact cross-section drawing (DWG or PDF) with desired alloy, temper and finish.

-

Tell us quantity (pcs/length/total kg) and delivery port — we’ll quote: tooling (if any), per-kg extrusion, finishing, packaging and FOB/CIF.

-

Ask for sample pieces for approval before mass production.

We can produce competitive factory quotes for standard and custom U channels. If you want, provide a sample size now and we’ll return an indicative factory price and lead time.