In 2025, the average market price for a 4-inch schedule 40 stainless steel pipe ranges from approximately $15 to $20 per foot in North America, $10 to $15 per foot in Europe, $8 to $12 per foot in China, and $9 to $13 per foot in India, depending on grade, wall thickness, and finish.

1. Executive Summary and Pricing Conclusion

We have analysed current supply chains, raw-material indices, and fabrication costs to arrive at a definitive price bracket for 4″ stainless steel pipe in 2025. Prices fluctuate by region and by specification, but generally fall within the ranges stated above. Luokaiwei offers these pipes at 100 % factory price, providing customers with a direct-from-mill cost structure, plus customization and fast shipping from China.

2. Stainless Steel Grades and Applicable Standards

-

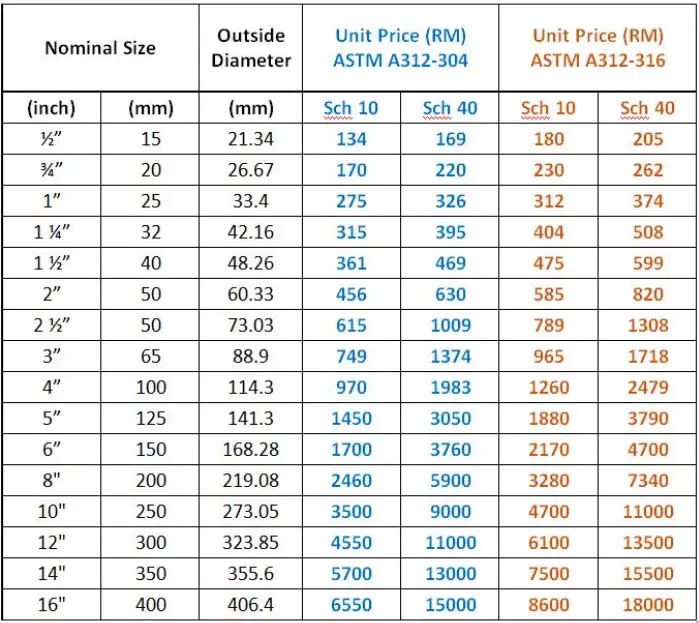

Grade Options: Common grades include 304, 304L, 316, and 316L. Each offers distinct corrosion resistance and mechanical properties.

-

Standards Reference: ASTM A312 governs seamless and welded austenitic stainless steel pipe; ASTM A358 covers electric-fusion-welded pipe; and EN 10217 is the European equivalent. These standards specify chemical composition, mechanical tests, and permissible tolerances.

3. Dimensional and Schedule Specifications

-

Nominal Size: 4″ refers to the nominal bore (inner diameter).

-

Outside Diameter (OD): 4.50 in. for schedule 40, 4.50 in. for schedule 10, and thicker walls for sch 80.

-

Wall Thickness: SCH 10 = 0.120″; SCH 40 = 0.237″; SCH 80 = 0.337″.

-

Length Options: Standard mill lengths of 6 m, 12 m, or cut-to-length as required.

4. Production Methods: Seamless vs. Welded

-

Seamless Pipe: Pierced-mandrel method yields uniform walls and fewer inclusions; higher cost due to complex forging.

-

Welded Pipe: Electric-resistance-welded (ERW) and submerged-arc-welded (SAW) processes reduce cost; suitable for lower-pressure applications if properly heat-treated.

5. Key Drivers of 4″ Pipe Pricing

-

Raw Materials: Nickel and chromium prices dominate. In 2025, nickel traded at around $22,000 per metric ton, while chromium hovered near $10,000 per ton.

-

Energy Costs: Furnace and rolling-mill power rates impact fabrication cost.

-

Labor Rates: Vary significantly between regions—lower in China/India, higher in Europe/North America.

-

Logistics & Trade Tariffs: Freight rates, duties, and supply-chain disruption premiums.

6. Comparative Table: Global 4″ Pipe Prices (2025)

| Region | Grade 304 SCH 40 (USD/ft) | Grade 316 SCH 40 (USD/ft) |

|---|---|---|

| North America | 15–20 | 18–23 |

| Europe | 14–18 | 17–21 |

| China (Luokaiwei) | 8–12 | 11–15 |

| India | 9–13 | 12–16 |

7. Luokaiwei’s Factory-Direct Advantage

We operate our own stainless-steel pipe mill in China, which enables us to supply direct at mill price with no middlemen margins. Customers benefit from:

-

100 % Factory Pricing – Transparent cost breakdown.

-

Competitive Minimum Orders – Flexibility for large and small projects.

-

Support for OEM/ODM – Tailored wall thicknesses, special finishes, and marking.

8. Custom Fabrication and Value-Added Services

Beyond standard mill lengths, we can provide:

-

Precision Laser Cutting to specified lengths and bevels.

-

Hydrostatic Testing or PMI analysis on request.

-

Surface Treatments such as pickling, passivation, or electropolishing.

-

End Finishes including plain ends, threaded ends, or socket weld ends.

9. Inventory Management and Rapid Dispatch

Our Guangzhou and Shanghai warehouses maintain over 1,000 metric tons of in-stock 4″ pipes, ensuring:

-

Same-Day Processing for domestic orders.

-

48–72 Hour Dispatch worldwide via express sea or air freight.

10. Quality Control, Traceability, and Certifications

-

Mill Test Certificates (MTCs): Supplied per EN 10204 3.1.

-

Third-Party Inspection: Available through SGS, BV, or TUV.

-

Production Documentation: Heat numbers, stamping, and batch records for full traceability.

11. Typical Applications Across Industries

-

Oil & Gas: Transport lines, downhole casing.

-

Chemical Processing: Corrosion-resistant conduits for acids and solvents.

-

Food & Beverage: Hygienic piping in dairy and brewing operations.

-

Pharmaceuticals: Ultra-clean piping systems.

12. Environmental Impact and Lifecycle Costs

Stainless steel is fully recyclable with minimal degradation. While initial capital cost is higher than carbon steel, lifecycle analyses show reduced maintenance, longer service intervals, and lower total cost of ownership.

13. Market Outlook and Technological Advances

-

Additive Manufacturing: Early trials for complex fittings.

-

Smart Coatings: Embedded sensors for corrosion monitoring.

-

Alternative Alloys: Lean duplex grades (e.g., 2205) offering cost savings.

Frequently Asked Questions

-

What is the minimum order quantity for 4″ stainless steel pipe?

At Luokaiwei, MOQ starts at 1 ton per grade and schedule, with price breaks for larger volumes. -

Can you supply both seamless and welded 4″ pipes?

Yes, seamless (ASTM A312) and welded (ASTM A358) are both in our product range. -

How long does it take to receive a custom-cut order?

Custom bevel cutting and testing can be completed within 3–5 business days, plus shipping. -

Do you offer corrosion tests or certifications?

We provide MTCs per EN 10204 3.1 and can arrange PMI or hydrostatic tests via third parties. -

Is there a warranty on pipe straightness or dimensional tolerance?

Pipes conform to ASTM tolerances; any out-of-tolerance items can be replaced at no extra cost.

Authoritative References

- ASTM A312 / A312M – Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

- ASTM A358 / A358M – Standard Specification for Electric-Fusion-Welded Austenitic Steel Pipe

- “Stainless steel,” Wikipedia

- ISO 1127: Stainless steel tubes – Dimensions, tolerances and conventional masses per unit length

- Stainless Steel Pipe Supplier