In the world of industrial piping, Sch 80 stainless steel pipes are widely recognized for their strength, durability, and versatile applications across various industries. These pipes are commonly used in construction, petrochemical, and manufacturing industries due to their ability to withstand high pressures and resist corrosion. The term "Sch 80" refers to the schedule number, which determines the wall thickness and pressure rating of the pipe. In this article, we will provide a detailed examination of Sch 80 stainless steel pipe dimensions, their various grades, standards, and applications. We will also explore the differences between various schedules and offer key considerations when choosing the right pipe for specific applications.

1. Understanding the Basics of Sch 80 Stainless Steel Pipes

Sch 80 stainless steel pipes are designed to handle high-pressure applications. The "Sch" in Sch 80 refers to the schedule, which determines the thickness of the pipe wall. A higher schedule number indicates a thicker wall, which translates to higher pressure resistance. For Sch 80, the wall thickness is significantly greater than for Sch 40 or Sch 10 pipes, making them ideal for more demanding applications.

2. Material Grades of Sch 80 Stainless Steel Pipes

Stainless steel pipes come in various grades, each offering unique properties. Common grades for Sch 80 stainless steel pipes include:

-

304 Stainless Steel: Known for its excellent corrosion resistance and good weldability. It is widely used in a variety of industries.

-

316 Stainless Steel: Offers superior resistance to corrosion, especially in chloride environments. It's ideal for marine applications.

-

310 Stainless Steel: This grade is resistant to high temperatures and oxidation, making it suitable for high-heat environments.

Understanding the material grade is crucial to determining the pipe’s suitability for specific applications, especially in harsh environments.

3. Sch 80 Pipe Dimensions: A Detailed Breakdown

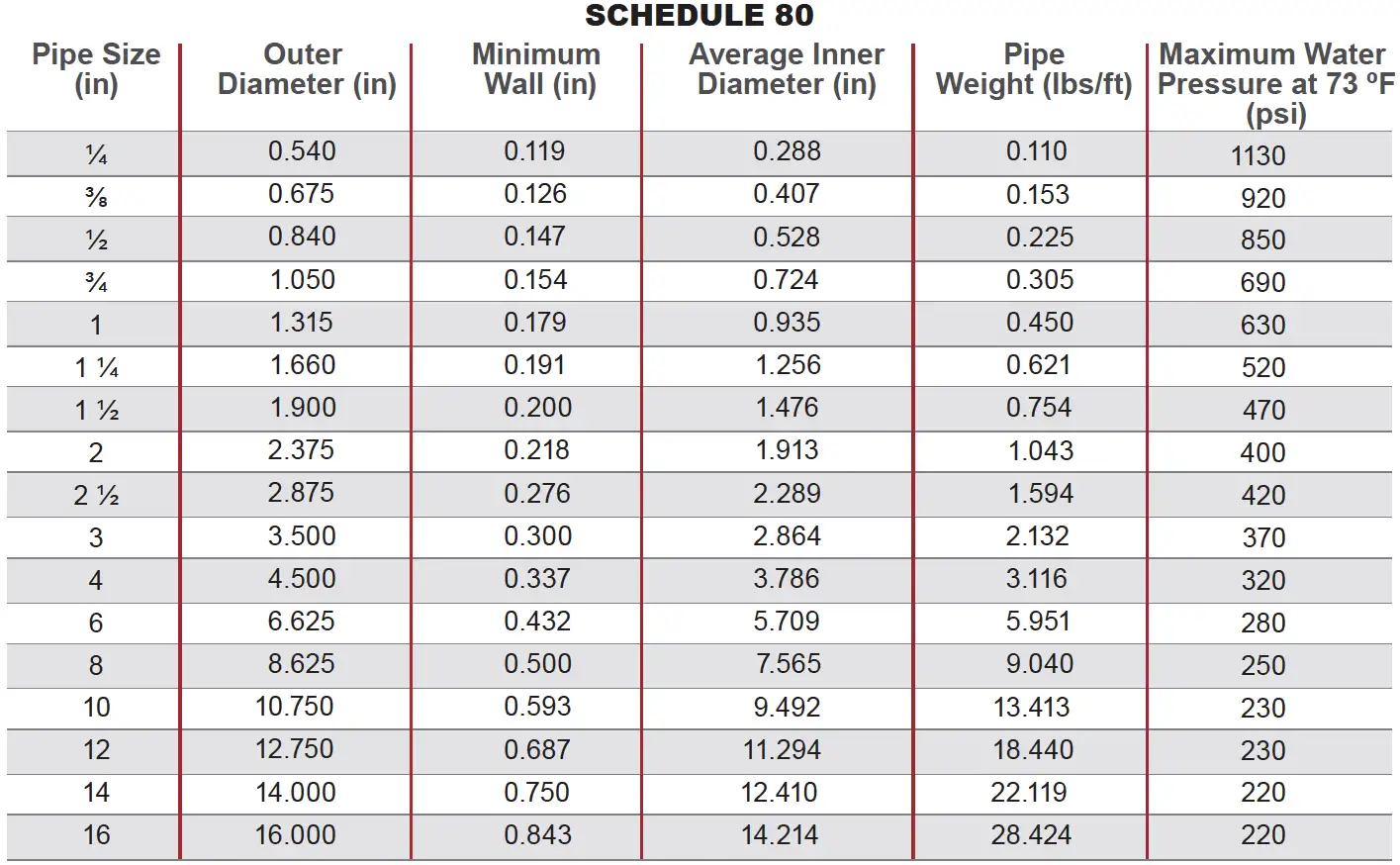

The dimensions of Sch 80 stainless steel pipes are defined by their nominal pipe size (NPS), which refers to the pipe's internal diameter. The actual external diameter (OD) is standardized across all schedules, but the wall thickness increases with higher schedule numbers. Below is a table outlining the key dimensions of Sch 80 stainless steel pipes.

| NPS (Inches) | Wall Thickness (Inches) | OD (Inches) | Weight per Foot (lbs) |

|---|---|---|---|

| 1/8 | 0.140 | 0.405 | 0.32 |

| 1/4 | 0.140 | 0.540 | 0.50 |

| 1/2 | 0.150 | 0.840 | 0.98 |

| 3/4 | 0.150 | 1.050 | 1.31 |

| 1 | 0.180 | 1.315 | 1.76 |

| 2 | 0.240 | 2.375 | 4.87 |

| 3 | 0.300 | 3.500 | 8.55 |

| 4 | 0.337 | 4.500 | 12.50 |

4. Pressure Rating and Strength

The pressure rating of Sch 80 stainless steel pipes is determined by the wall thickness, material grade, and temperature. These pipes are designed to handle high-pressure applications, and their pressure ratings are among the highest in the industry for standard stainless steel pipes. For example, a 1-inch Sch 80 stainless steel pipe can withstand up to 1,900 psi at room temperature, while a 2-inch pipe can handle up to 1,200 psi.

5. Applications of Sch 80 Stainless Steel Pipes

Sch 80 stainless steel pipes are used in various sectors due to their strength and corrosion resistance. Some common applications include:

-

Chemical Processing: For transporting chemicals under high pressure.

-

Oil and Gas: In pipelines for transporting crude oil, natural gas, and other petroleum products.

-

Food and Beverage: In the production of stainless steel equipment and piping systems due to hygiene standards.

-

Construction: In structural supports and systems where high strength is required.

6. Comparing Sch 80 to Other Schedules

When selecting the right schedule, it's important to compare Sch 80 with other commonly used schedules, such as Sch 40 and Sch 160. Below is a table comparing the key differences:

| NPS (Inches) | Sch 40 Wall Thickness (Inches) | Sch 80 Wall Thickness (Inches) | Sch 160 Wall Thickness (Inches) |

|---|---|---|---|

| 1/2 | 0.109 | 0.150 | 0.250 |

| 1 | 0.140 | 0.180 | 0.280 |

| 2 | 0.154 | 0.240 | 0.375 |

| 3 | 0.216 | 0.300 | 0.406 |

As shown in the table, Sch 80 pipes have thicker walls compared to Sch 40, providing higher pressure tolerance. However, they are not as thick as Sch 160, making them a balance between strength and cost.

7. Manufacturing Standards and Specifications

Sch 80 stainless steel pipes adhere to industry standards such as ASTM A312, ASTM A312M, and ANSI B36.10M. These standards define the dimensional tolerances, material properties, and testing requirements to ensure that the pipes meet the necessary performance criteria. Pipes manufactured to these standards are certified for use in a variety of critical applications.

8. Cost Considerations

The cost of Sch 80 stainless steel pipes is influenced by several factors, including material grade, pipe size, and manufacturing process. Typically, Sch 80 pipes are more expensive than Sch 40 pipes due to their thicker walls and enhanced performance characteristics. However, their price is generally lower than Sch 160 pipes.

9. Installation and Maintenance

Installing Sch 80 stainless steel pipes requires proper welding and sealing techniques to ensure leak-free operation. Maintenance typically involves periodic inspections for corrosion or wear, especially in high-pressure environments. Regular maintenance can significantly extend the lifespan of these pipes.

10. Advantages of Using Sch 80 Stainless Steel Pipes

-

High Strength: Sch 80 pipes offer superior strength compared to lower schedule pipes.

-

Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, making it ideal for harsh environments.

-

Durability: The thick walls provide enhanced durability, even under high-pressure conditions.

-

Versatility: Suitable for a wide range of applications across different industries.

11. Challenges and Considerations

Despite their advantages, Sch 80 stainless steel pipes have certain limitations. The increased wall thickness makes them less flexible, and they may require specialized tools for installation. Additionally, the higher cost may be a factor to consider for budget-sensitive projects.

12. Conclusion

Sch 80 stainless steel pipes are essential components in a variety of industries due to their high strength, resistance to corrosion, and ability to withstand high pressures. Understanding their dimensions, pressure ratings, and applications will help you select the right pipe for your specific needs. By carefully considering the material, schedule, and standards, you can ensure optimal performance and longevity for your piping systems.

FAQs

-

What is the difference between Sch 80 and Sch 40 pipes?

Sch 80 pipes have thicker walls, which makes them more suitable for high-pressure applications compared to Sch 40 pipes. -

Can Sch 80 pipes be welded?

Yes, Sch 80 stainless steel pipes can be welded using standard welding techniques. -

What is the maximum pressure rating for Sch 80 pipes?

Sch 80 pipes can withstand pressures up to 1,900 psi for a 1-inch pipe at room temperature. -

Are Sch 80 pipes suitable for marine environments?

Yes, Sch 80 pipes made from 316 stainless steel offer excellent corrosion resistance, making them ideal for marine environments. -

How do I choose between Sch 80 and Sch 160 pipes?

If your application involves extremely high-pressure environments, Sch 160 may be more suitable. However, Sch 80 provides a good balance of strength and cost.