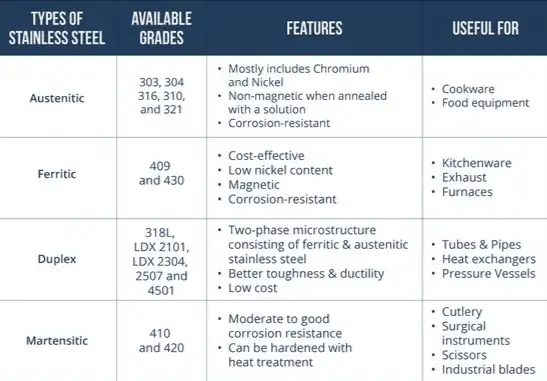

Stainless steel is categorized into five primary families—Austenitic, Ferritic, Martensitic, Duplex, and Precipitation-Hardening—each defined by its metallurgical structure and alloying elements. These families encompass hundreds of specific grades tailored for diverse applications in food processing, chemical plants, architecture, automotive, and medical devices. Understanding the distinctions between each family and key grades enables engineers to optimize material selection for corrosion resistance, mechanical performance, fabrication ease, and cost-effectiveness.

1. Introduction to Stainless Steel

Stainless steels are iron–chromium alloys containing at least 10.5% chromium, which forms a passive Cr₂O₃ film for corrosion resistance. Additional alloying elements—nickel, molybdenum, nitrogen, and carbon—tune properties such as strength, weldability, and pitting resistance. The five structural families are defined by crystal phase and heat-treatment behavior.

2. Classification of Stainless Steel Families

2.1 Austenitic Stainless Steel

- Structure: Face-centered cubic (γ-phase)

- Alloying: ≥16% Cr, 6–22% Ni, ≤0.08% C; often N for strength

- Grades: 200-series (Cr-Mn-N), 300-series (Cr-Ni) such as 304, 316

- Key Traits:

- Non-magnetic, excellent formability & weldability

- Wide temperature range; cryogenic toughness

- Not heat-treatable for hardness; work-hardening only

- Applications: Food equipment, chemical tanks, architectural facades

2.2 Ferritic Stainless Steel

- Structure: Body-centered cubic (α-phase)

- Alloying: 10.5–30% Cr, very low C, Ni-free

- Grades: 400-series such as 430, 441, 444

- Key Traits:

- Magnetic, good resistance to stress-corrosion cracking

- Limited formability, moderate strength

- Not hardenable by heat treatment

- Applications: Automotive exhausts, kitchen sinks, industrial panels

2.3 Martensitic Stainless Steel

- Structure: Body-centered tetragonal (martensite) after quench

- Alloying: 11.5–18% Cr, 0.1–1.2% C

- Grades: 410, 420, 440C

- Key Traits:

- Heat-treatable to high hardness (up to 60+ HRC)

- Moderate corrosion resistance, magnetic

- Good wear resistance

- Applications: Cutlery, surgical instruments, shafts, valves

2.4 Duplex Stainless Steel

- Structure: Mixed austenite + ferrite (~50/50)

- Alloying: 19–28% Cr, 4–8% Ni, 2.5–5% Mo, + 0.05–0.50% N

- Grades: 2205, 2507 (Super Duplex)

- Key Traits:

- High strength (∼2× austenitic); excellent pitting & SCC resistance

- Moderate formability, good weldability with controlled heat input

- Applications: Offshore platforms, chemical tanks, pulp & paper equipment

2.5 Precipitation-Hardening (PH) Stainless Steel

- Structure: Initially austenitic; hardened by aging

- Alloying: 12–17% Cr, 3–7% Ni, additions of Al, Ti, Cu

- Grades: 17-4 PH, 15-5 PH, 13-Cr-4 Ni Cu Mo

- Key Traits:

- Heat-treatable to high strength (900–1200 MPa)

- Good corrosion resistance, moderate formability

- Widely used in aerospace and tooling

- Applications: Aircraft components, fasteners, nuclear waste containers.

3. Chemical Composition & Mechanical Properties

| Family | Cr (%) | Ni (%) | Mo (%) | C (%) | Tensile (MPa) | Hardness (HRC) | Magnetic |

|---|---|---|---|---|---|---|---|

| Austenitic (304) | 18–20 | 8–10 | — | ≤0.08 | 515–720 | 70 HV typ. | No |

| Ferritic (430) | 16–18 | — | — | ≤0.12 | 450–620 | 150–210 HV | Yes |

| Martensitic (420) | 12–14 | — | — | 0.15–0.40 | 550–900 | 40–50 HRC | Yes |

| Duplex (2205) | 22–23 | 5–6 | 3–3.5 | ≤0.03 | 620–850 | 32–38 HRC | Partial |

| PH (17-4 PH) | 15–17 | 3–5 | — | ≤0.07 | 860–1380 | 30–42 HRC | No |

4. Corrosion Resistance Comparison

- Austenitics: Excellent general corrosion; 316 adds Mo for chlorides.

- Ferritics: Good oxidation, moderate pitting.

- Martensitics: Fair resistance; best in dry or mild environments.

- Duplex: Superior pitting and stress-crack resistance; high PREN.

- PH Grades: Comparable to 304/316 in standard conditions.

5. Fabrication & Heat-Treatment

| Process | Austenitic | Ferritic | Martensitic | Duplex | PH |

|---|---|---|---|---|---|

| Forming | Excellent | Moderate | Fair | Limited | Fair |

| Welding | Very good | Good (low Ni) | Heat pre-heat & post-heat required | Careful heat input | Standard SS practices |

| Hardening | Work-hardening only | — | Quench & temper to high HRC | Solution + age optional | Solution + age treatment |

| Machining | Work-hardens, moderate | Moderate | Challenging at high hardness | Moderate | Moderate |

6. Industry Applications

| Family | Key Sectors |

|---|---|

| Austenitic | Food, Pharma, Architecture, Cryogenics |

| Ferritic | Automotive, Appliances, Building Panels |

| Martensitic | Cutlery, Surgical Tools, Pumps & Rotors |

| Duplex | Oil & Gas, Pulp & Paper, Chemical Vessels |

| PH | Aerospace, Nuclear, High-pressure Fittings |

7. Selection Criteria & Decision Guide

- Corrosion Environment:

- Chlorides or acids → Duplex or 316/317

- Mild environment → 304 or 430

- Strength Needs:

- High yield strength → Duplex or PH grades

- Moderate strength → Austenitic

- Fabrication Ease:

- Complex forming → Austenitic

- Simple shapes → Ferritic or Martensitic

- Magnetic Requirements:

- Non-magnetic → Austenitic or PH

- Magnetic → Ferritic, Martensitic, Duplex

8. Market Trends & Sustainability

- Recycled Content: Stainless steels often contain ≥60% recycled scrap.

- Price Drivers: Nickel and molybdenum markets heavily influence austenitic and duplex costs.

- Green Initiatives: Demand rising for lower-Ni 200-series and higher-recycled content grades.

9. Emerging Technologies

- Advanced High-Strength Duplexes: Engineered for thinner sections in offshore.

- Additive Manufacturing: 316L and PH powders for intricate components.

- Surface Nano-engineering: PVD coatings on martensitic blades for wear & corrosion.

10. FAQs

- Which stainless family is best for marine environments?

Duplex (e.g., 2205) and 316 austenitics offer top chloride resistance. - Can ferritic stainless steels be hardened?

No—ferritics are not hardenable by heat treatment; strength gained via cold work. - Why choose 17-4 PH over 304?

For applications requiring both corrosion resistance and high strength (up to 1380 MPa).

Conclusion

Selecting the right stainless steel type hinges on balancing corrosion resistance, mechanical performance, fabrication ease, magnetic properties, and cost. This guide’s classification framework, property matrices, and decision criteria will help you pinpoint the optimal family and grade for any demanding application.