Custom 80/20 Aluminum For Sale Prices 2025

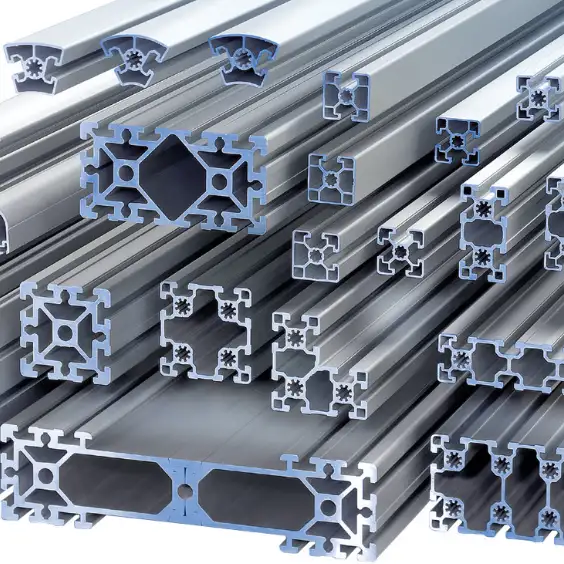

80/20 aluminum, commonly known as aluminum 80/20, is a versatile and highly durable material that is widely used in various industries. Its popularity stems from its impressive combination of strength, light weight, corrosion resistance, and ease of fabrication. This alloy has found applications in everything from construction and aerospace to machinery and furniture manufacturing. 1. […]

Custom 80/20 Aluminum For Sale Prices 2025 Read More »