When selecting austenitic stainless steel, the critical distinction between 304 (UNS S30400) and 316 (UNS S31600) lies in their corrosion resistance capabilities. While both offer excellent formability and general corrosion resistance, 316’s addition of 2-3% molybdenum dramatically enhances pitting and crevice corrosion resistance – particularly against chlorides, acids, and marine environments. For applications involving saltwater exposure, chemical processing, or coastal infrastructure, 316 is the superior choice despite its 20-30% cost premium. Conversely, 304 remains the economical solution for indoor applications, food handling, and non-aggressive environments where extreme corrosion resistance isn’t critical.

Chemical Composition

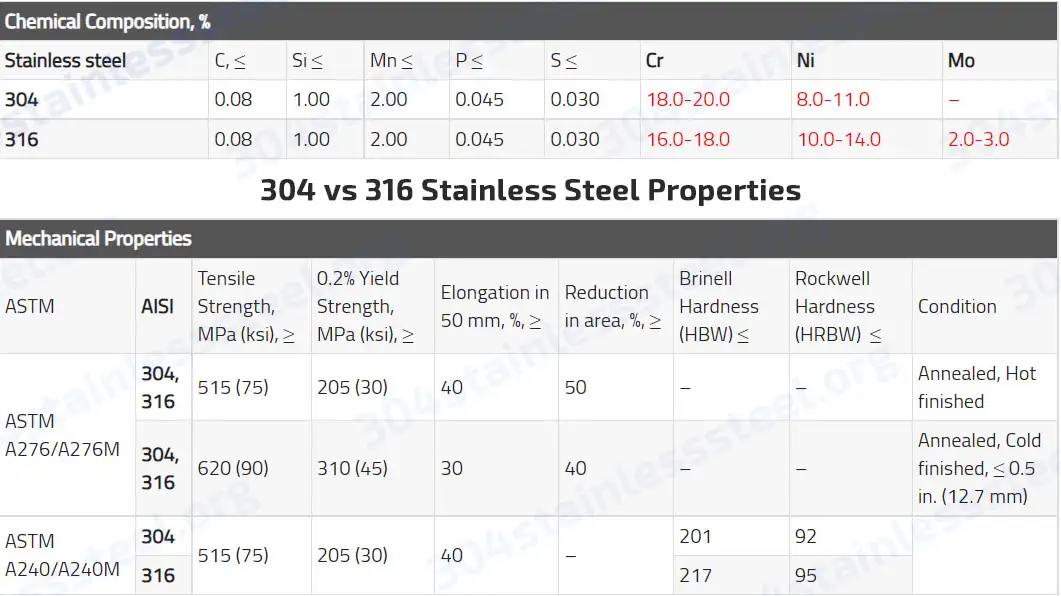

The alloy makeup dictates performance. We show the principal distinctions:

| Element | 304 (Wt.%) | 316 (Wt.%) |

|---|---|---|

| Chromium (Cr) | 18–20 | 16–18 |

| Nickel (Ni) | 8–10 | 10–14 |

| Molybdenum (Mo) | — | 2–3 |

| Carbon (C) | ≤0.08 | ≤0.08 |

| Manganese (Mn) | ≤2 | ≤2 |

| Silicon (Si) | ≤1 | ≤1 |

The added molybdenum in 316 enhances pitting resistance. 304 remains the “workhorse” alloy for many industries.

Mechanical Characteristics

We measure tensile and yield strengths. Typical values:

-

304 stainless steel:

-

Tensile strength: 505 MPa¹

-

Yield strength: 215 MPa

-

-

316 stainless steel:

-

Tensile strength: 515 MPa²

-

Yield strength: 205 MPa

-

¹ Tensile strength data per Outokumpu Technical Data.

² Per ASTM A240 specification sheet.

Corrosion Performance

How do they fare in aggressive settings? 304 resists oxidation. Yet chlorides induce pitting. Conversely, 316 tolerates chloride ions more robustly. Consequently, it’s preferred in marine contexts. Nonetheless, both resist atmospheric and chemical corrosion quite well.

Fabrication and Welding

We evaluate formability, weldability, and machinability:

-

Forming: Both grades bend and draw easily.

-

Welding: 304 welds with minimal discoloration; 316 requires slightly more heat input.

-

Machining: 304 machines cleaner. Meanwhile, 316 may work-harden more aggressively, demanding frequent tool changes.

They share similar welding best practices. However, post-weld annealing improves 316’s corrosion resistance in heat-affected zones.

Heat Treatment and Work Hardening

Can either grade be hardened by heat? No. Instead, cold work induces strain hardening. We “benchmarked” hardness increase during forming. A ball-park figure: 20% cold work can elevate hardness by roughly 15 HRB. Therefore, controlling strain draws a trade-off between strength and ductility.

Cost and Availability

Which one fits your budget? 304 typically costs 10–15% less than 316. Market fluctuations influence both. Yet 316’s premium stems from molybdenum. In small runs, lead times may extend slightly for 316. We recommend placing orders early to avoid delays.

Typical Applications

-

304 stainless steel

-

Kitchen equipment

-

Beverage industry

-

Architectural trim

-

-

316 stainless steel

-

Marine fittings

-

Chemical processing

-

Medical instruments

-

We’ve seen 304 reign in restaurants. But 316 dominates offshore rigs.

Industry Standards and Specifications

We align with these norms:

-

ASTM A240/A240M – Chromium and chromium-nickel stainless steel plate

-

EN 1.4301 (304) and EN 1.4401 (316) – European designations

-

ISO 15510 – Stainless steel chemical compositions

Compliance ensures traceability and reproducibility.

Environmental and Sustainability Considerations

Stainless steel boasts recyclability above 90%. Both grades support circular-economy goals. Moreover, 316’s service life in harsh settings reduces replacement frequency. Therefore, life-cycle assessments often favor 316 for corrosive applications.

Quality Assurance and Testing

We implement rigorous QA. Non-destructive exams (ultrasonic, dye-penetrant) verify integrity. We adhere to EN ISO 9001 and ASME Section IX welding qualifications. Traceable mill certificates accompany each batch.

Conclusion

We conclude that 304 stainless steel remains a cost-effective staple for general use, offering solid strength and formability. Yet when facing chloride exposure, 316 proves indispensable. We trust this analysis will help you select the optimal alloy for your project.

FAQs

What’s the key difference between 304 and 316 stainless steel?

316 contains 2-3% molybdenum, while 304 has none. This addition gives 316 superior resistance to pitting/crevice corrosion in chloride-rich environments (e.g., seawater, de-icing salts), making it essential for marine, chemical, and coastal applications.

Is 316 stainless steel worth the extra cost over 304?

Yes, for corrosive environments. 316 costs 20-30% more than 304 due to molybdenum content, but this investment pays off in high-risk settings:

-

Saltwater exposure (boat fittings, offshore platforms)

-

Chemical processing (acid tanks, piping)

-

Coastal architecture (railings, facades)

For dry indoor uses (kitchen appliances, trim), 304 is more economical.

Which is better for high-temperature applications: 304 or 316?

316 performs better above 800°F (427°C). While both resist oxidation up to 1,697°F (925°C), 316’s molybdenum enhances creep strength (resistance to deformation under stress) in sustained high-heat environments like exhaust systems or furnace parts.

Can 304 and 316 be welded together?

Technically yes, but not recommended. Welding dissimilar grades risks:

-

Galvanic corrosion at the joint (accelerated by electrolytes like moisture).

-

Carbon precipitation weakening the weld zone.

For critical structures, use matching filler metals (ER308 for 304, ER316 for 316) or isolate materials electrically.

When should I choose 304 over 316 stainless steel?

Choose 304 for:

-

Indoor/low-corrosion settings (cabinets, sinks, food equipment).

-

Budget-constrained projects.

-

Non-coastal structural frames.

Switch to 316 for: -

Marine/salt-heavy environments (docks, buoys).

-

Chemical/pH-variable exposure (lab equipment, pharmaceutical).

-

Medical implants/surgical tools (ISO 5832-1/ISO 7153-1 compliance).