Regular aluminum, which encompasses cast, rolled, and forged forms, differs significantly from extruded aluminum in terms of production methods, structural properties, and practical applications. Understanding these differences is crucial for making informed decisions in construction, automotive, aerospace, and countless other industries where aluminum plays a vital role.

Understanding Regular Aluminum: The Foundation of Metal Manufacturing

Regular aluminum typically refers to aluminum products manufactured through traditional processes such as casting, rolling, forging, or machining. These methods have been the backbone of aluminum production for decades, creating everything from engine blocks to aircraft components.

Cast aluminum represents the most common form of regular aluminum production. During this process, molten aluminum is poured into molds and allowed to solidify. The resulting products often exhibit excellent dimensional stability and can accommodate complex geometries that would be challenging to achieve through other methods. However, cast aluminum parts may contain internal voids or inconsistencies that can affect their mechanical properties.

Rolled aluminum involves passing aluminum through a series of rollers to create sheets, plates, or foils of specific thicknesses. This process creates products with uniform thickness and excellent surface finish, making it ideal for applications requiring precise dimensional control. The rolling process also work-hardens the material, potentially improving its strength characteristics.

Forged aluminum undergoes mechanical deformation under high pressure, creating parts with superior grain structure and mechanical properties. This method produces components with exceptional strength-to-weight ratios, making forged aluminum particularly valuable in aerospace and automotive applications where performance is paramount.

The Extrusion Process: Transforming Aluminum Through Pressure

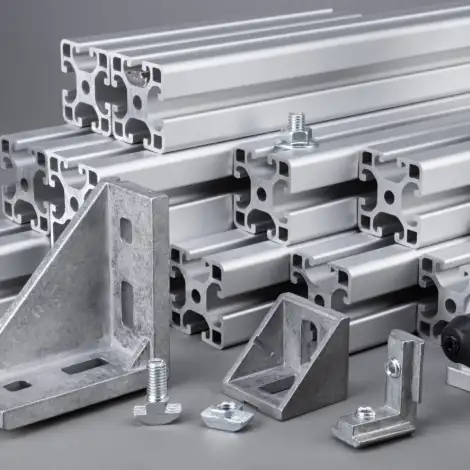

Extruded aluminum represents a fundamentally different approach to aluminum manufacturing. During extrusion, heated aluminum billets are forced through specially designed dies under tremendous pressure, creating continuous profiles with consistent cross-sections.

The extrusion process begins with aluminum billets heated to approximately 800-900°F (425-480°C). These heated billets are then placed in an extrusion press where a hydraulic ram applies pressure ranging from 1,000 to 15,000 tons, depending on the profile complexity and aluminum alloy being processed.

What makes extrusion particularly fascinating is its ability to create complex cross-sectional shapes that would be impossible or extremely expensive to produce through traditional machining methods. The continuous nature of the process allows for the creation of profiles with internal cavities, multiple chambers, and intricate geometries while maintaining consistent wall thickness throughout the entire length.

The cooling process following extrusion is equally important. Controlled cooling rates affect the final mechanical properties of the extruded aluminum, influencing factors such as strength, ductility, and corrosion resistance. Many extruded products undergo additional heat treatment processes to optimize their performance characteristics for specific applications.

Mechanical Properties: A Comparative Analysis

The mechanical properties of regular aluminum versus extruded aluminum vary significantly based on the specific manufacturing process and alloy composition. However, certain general trends emerge when comparing these two categories.

Extruded aluminum often exhibits superior strength characteristics compared to cast aluminum due to the intense pressure and controlled cooling involved in the extrusion process. The mechanical working during extrusion creates a more refined grain structure, resulting in improved tensile strength and fatigue resistance.

Regular aluminum, particularly rolled and forged varieties, can achieve excellent mechanical properties through work hardening and heat treatment. Forged aluminum components often surpass extruded aluminum in terms of ultimate strength, making them preferred for high-stress applications such as aircraft landing gear components.

The directional properties of extruded aluminum represent both an advantage and a limitation. Extruded profiles typically exhibit their highest strength parallel to the extrusion direction, with somewhat reduced properties in the transverse direction. This anisotropic behavior must be considered during design and application.

Surface finish quality also differs between these aluminum types. Extruded aluminum typically has an excellent surface finish directly from the extrusion process, often requiring minimal additional finishing operations. Regular aluminum products may require additional machining or surface treatment to achieve comparable finish quality.

Cost Considerations and Economic Factors

The economic implications of choosing between regular aluminum and extruded aluminum extend beyond simple material costs. Manufacturing complexity, tooling requirements, and production volumes all influence the total cost equation.

Extruded aluminum offers significant advantages in high-volume applications due to the continuous nature of the process. Once extrusion dies are created, the per-unit cost of extruded profiles decreases dramatically with increased production volumes. However, the initial die costs can be substantial, particularly for complex profiles.

Regular aluminum manufacturing methods often require less initial tooling investment, making them more suitable for low-volume or prototype applications. Machining costs for regular aluminum can be higher due to the need for secondary operations to achieve final dimensions and surface finishes.

The material utilization efficiency also differs between these approaches. Extrusion typically achieves excellent material utilization rates, with minimal waste generation. Traditional machining of regular aluminum often results in significant material waste, particularly for complex geometries.

Applications and Industry Usage Patterns

| Application Category | Regular Aluminum | Extruded Aluminum | Primary Advantage |

|---|---|---|---|

| Automotive Components | Engine blocks, wheels | Heat exchangers, structural frames | Regular: Complex geometries<br>Extruded: Cost efficiency |

| Construction | Structural beams, plates | Window frames, curtain walls | Regular: Load bearing<br>Extruded: Weather resistance |

| Aerospace | Landing gear, engine parts | Cabin interior, ducting | Regular: High strength<br>Extruded: Weight reduction |

| Electronics | Heat sinks, housings | Enclosures, profiles | Regular: Thermal mass<br>Extruded: Custom shapes |

| Consumer Products | Cookware, appliances | Furniture, decorative items | Regular: Durability<br>Extruded: Aesthetic appeal |

The construction industry represents one of the largest consumers of extruded aluminum, utilizing profiles for window frames, curtain wall systems, and structural components. The ability to create hollow profiles with excellent strength-to-weight ratios makes extruded aluminum particularly attractive for these applications.

Automotive manufacturers increasingly rely on extruded aluminum for heat exchangers, structural components, and crash management systems. The consistent cross-sectional properties and excellent corrosion resistance of extruded aluminum make it ideal for these demanding applications.

Regular aluminum maintains its dominance in applications requiring complex three-dimensional shapes or exceptional mechanical properties. Cast aluminum engine blocks, forged suspension components, and machined aerospace parts continue to rely on traditional aluminum manufacturing methods.

Surface Treatment and Finishing Options

The surface treatment possibilities for regular aluminum and extruded aluminum differ significantly, influencing both appearance and performance characteristics. Understanding these differences is essential for achieving optimal results in various applications.

Extruded aluminum profiles often undergo anodizing treatments immediately following the extrusion process. The uniform surface condition and consistent alloy composition of extruded aluminum make it ideal for anodizing, resulting in excellent corrosion resistance and aesthetic appeal. The anodizing process can be performed in various colors and finishes, providing designers with extensive customization options.

Regular aluminum components may require additional surface preparation before anodizing or other treatments. Cast aluminum surfaces often need machining or chemical etching to achieve the uniformity required for high-quality anodizing. However, the flexibility in alloy selection for regular aluminum can provide advantages in certain coating applications.

Powder coating represents another popular finishing option for both aluminum types. Extruded aluminum profiles are particularly well-suited for powder coating due to their consistent cross-sectional geometry and excellent surface condition. The thermal properties of extruded aluminum also contribute to uniform coating application and curing.

Environmental Impact and Sustainability Considerations

The environmental implications of aluminum production and processing have become increasingly important in recent years. Both regular aluminum and extruded aluminum manufacturing processes have distinct environmental footprints that must be considered.

Extruded aluminum production typically requires less energy per unit mass compared to casting processes, particularly when considering the minimal waste generation and high material utilization rates. The continuous nature of extrusion also allows for better energy management and heat recovery systems.

Regular aluminum production, particularly casting operations, often involves higher energy consumption due to the need for repeated melting and cooling cycles. However, the flexibility in alloy composition and the ability to incorporate high percentages of recycled content can offset some environmental impacts.

The recyclability of both aluminum types remains excellent, with aluminum maintaining its properties through multiple recycling cycles. This characteristic makes aluminum one of the most sustainable metals available, regardless of the specific manufacturing process employed.

Case Study: Automotive Heat Exchanger Development

A leading automotive manufacturer recently faced the challenge of developing a new heat exchanger design for their latest hybrid vehicle platform. The application required exceptional thermal performance, corrosion resistance, and weight optimization while maintaining cost competitiveness.

Initially, the engineering team considered using regular aluminum through a combination of casting and machining processes. This approach would have provided excellent design flexibility and the ability to incorporate complex internal geometries. However, preliminary cost analysis revealed that the machining operations required to achieve the necessary surface finish and dimensional accuracy would result in material waste exceeding 40%.

The team then evaluated extruded aluminum profiles with subsequent joining operations. By carefully designing the extrusion dies, they could create profiles with optimized fin geometries and internal flow channels. The extruded approach reduced material waste to less than 5% while achieving superior thermal performance due to the consistent wall thickness and grain structure.

The final design incorporated multiple extruded aluminum profiles joined through friction stir welding, creating a heat exchanger that exceeded performance targets while reducing weight by 18% compared to the original cast aluminum design. Production costs decreased by 25% due to reduced machining requirements and improved material utilization.

This case study illustrates how the choice between regular aluminum and extruded aluminum can significantly impact both performance and economics in real-world applications. The key to success was matching the manufacturing process to the specific requirements of the application rather than defaulting to traditional approaches.

Quality Control and Testing Standards

Quality control requirements for regular aluminum and extruded aluminum differ significantly due to their distinct manufacturing processes and typical applications. Understanding these requirements is essential for ensuring product reliability and regulatory compliance.

Extruded aluminum products typically undergo dimensional inspection using coordinate measuring machines or optical scanning systems. The continuous nature of the extrusion process allows for real-time monitoring of critical dimensions, enabling immediate process adjustments when variations are detected.

Regular aluminum components often require more extensive testing protocols due to the potential for internal defects. Non-destructive testing methods such as ultrasonic inspection, radiographic testing, and magnetic particle inspection are commonly employed to detect internal voids, cracks, or inclusions.

Mechanical property testing follows standardized protocols for both aluminum types, with testing frequency and sample selection varying based on the specific application requirements. Critical aerospace components may require testing of every batch, while commercial building applications may utilize statistical sampling approaches.

Future Trends and Technological Developments

The aluminum industry continues to evolve, with new technologies and processes emerging that blur the traditional boundaries between regular aluminum and extruded aluminum. Advanced manufacturing techniques such as additive manufacturing and hybrid processing are creating new possibilities for aluminum component production.

Friction stir processing represents one promising development that can enhance the properties of both regular and extruded aluminum. This solid-state process can refine grain structure, eliminate defects, and even create functionally graded materials with varying properties across a single component.

Digital manufacturing technologies are also transforming aluminum production. Real-time monitoring systems, predictive maintenance algorithms, and artificial intelligence-driven process optimization are improving both quality and efficiency across all aluminum manufacturing processes.

The integration of recycled content continues to increase, with new alloy development focusing on maintaining performance while incorporating higher percentages of recycled aluminum. This trend affects both regular aluminum and extruded aluminum production, though the specific challenges and opportunities vary between these approaches.

Frequently Asked Questions

Q: Can extruded aluminum be as strong as forged aluminum? A: While extruded aluminum can achieve excellent strength properties, forged aluminum typically provides superior strength characteristics due to the intense mechanical working involved in the forging process. However, extruded aluminum offers better strength-to-weight ratios in many applications and can be engineered to meet specific strength requirements through alloy selection and heat treatment.

Q: Why is extruded aluminum more expensive than cast aluminum for small quantities? A: The higher cost of extruded aluminum in small quantities primarily stems from die manufacturing costs. Extrusion dies are expensive to design and manufacture, making the per-unit cost high for small production runs. Cast aluminum uses reusable molds that can be more cost-effective for low-volume applications.

Q: Which aluminum type is better for outdoor applications? A: Both aluminum types can perform well in outdoor applications, but extruded aluminum often has advantages due to its consistent alloy composition and excellent surface finish that facilitates high-quality anodizing or coating. The choice depends on specific environmental conditions and design requirements.

Q: Can regular aluminum be recycled as easily as extruded aluminum? A: Both aluminum types are equally recyclable, maintaining their properties through multiple recycling cycles. The recycling process is primarily concerned with alloy composition rather than the original manufacturing method, making aluminum one of the most sustainable metals available.

Q: How do I choose between regular aluminum and extruded aluminum for my project? A: The choice depends on factors including production volume, geometric complexity, strength requirements, surface finish needs, and cost considerations. Extruded aluminum excels in high-volume applications with consistent cross-sections, while regular aluminum offers advantages for complex three-dimensional shapes and specialized mechanical properties.

Conclusion

The distinction between regular aluminum and extruded aluminum extends far beyond simple manufacturing methods. These approaches represent different philosophies in metal processing, each with unique advantages and limitations that must be carefully considered in the context of specific applications.

Regular aluminum, with its versatility in casting, rolling, and forging, continues to serve critical roles in applications requiring complex geometries, exceptional mechanical properties, or specialized alloy compositions. The maturity of these processes and the extensive knowledge base surrounding them provide confidence in demanding applications where performance cannot be compromised.

Extruded aluminum offers compelling advantages in applications that can benefit from its consistent cross-sectional properties, excellent surface finish, and cost-effective high-volume production characteristics. The ability to create complex profiles with minimal waste and excellent dimensional control makes extrusion particularly attractive for modern manufacturing requirements.

The future of aluminum manufacturing will likely see continued convergence of these approaches, with hybrid processes and advanced technologies creating new possibilities for aluminum component production. Understanding the fundamental differences between regular aluminum and extruded aluminum remains essential for making informed decisions that optimize performance, cost, and sustainability in an increasingly competitive global marketplace.

Success in aluminum selection requires careful consideration of all factors including mechanical requirements, production volumes, cost constraints, and environmental considerations. By matching the manufacturing process to the specific application requirements, engineers and designers can achieve optimal results that meet both immediate needs and long-term objectives.

References

- Aluminum Association - Aluminum Basics and Properties

- NIST - Materials Science and Engineering Division: Aluminum Alloys

- ASTM International - Aluminum Standards and Testing Methods

- ISO - International Standards for Aluminum and Aluminum Alloys

- Wikipedia - Aluminium Extrusion Process and Applications