A standard 4x8 sheet of aluminum typically weighs between 24 and 48 pounds (10.88 to 21.77 kilograms), depending on the thickness and alloy of the material. To be more specific, the weight of a 4x8 sheet of aluminum is directly proportional to its thickness and alloy type. For instance, a 0.125-inch (1/8-inch) thick sheet made of 6061-T6 aluminum weighs around 40 pounds, while a thinner 0.050-inch sheet weighs much less. The density of aluminum is an important factor in determining its weight, and different alloys can affect the weight as well.

1. Introduction

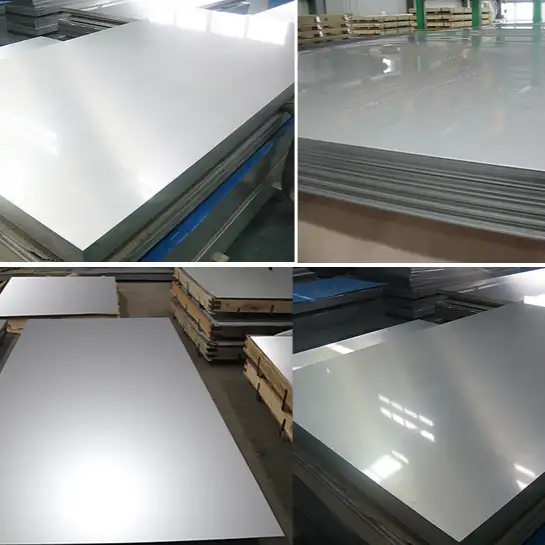

Aluminum is widely used across various industries due to its lightweight nature, corrosion resistance, and versatility. When considering the material for a project, it's important to know the weight of the aluminum sheets, especially when dealing with large sheets like the 4x8 format.

Aluminum is measured by its density, which is approximately 2.70 g/cm³ (0.098 lbs/in³). This density plays a key role in determining how much a 4x8 sheet will weigh, but thickness and alloy choice are just as important. The following sections will break down these calculations and provide further insights into the practical applications.

2. Understanding Aluminum Alloys

Aluminum is available in various alloys, with each offering different physical properties, such as strength, weight, and resistance to corrosion. The most common alloys used for sheets are:

-

6061-T6: A versatile alloy that is lightweight yet strong, often used in the aerospace and construction industries.

-

3003-H14: A general-purpose alloy, commonly used in kitchen appliances, roofing, and siding.

-

5052-H32: Known for its corrosion resistance, this alloy is used in marine environments.

The alloy's composition affects not only its weight but also its performance in specific applications. The heavier alloys are stronger and can bear more load, while the lighter alloys are better for applications where weight reduction is crucial.

3. How to Calculate the Weight of a 4x8 Sheet of Aluminum

To calculate the weight of an aluminum sheet, the formula is:

Weight=Length×Width×Thickness×Density

Where:

-

Length = 4 feet (48 inches)

-

Width = 8 feet (96 inches)

-

Thickness = varies based on the sheet

-

Density = 2.70 g/cm³ or 0.098 lbs/in³

For example, a 0.125-inch (1/8-inch) thick 4x8 sheet of 6061-T6 aluminum will have a weight calculated as follows:

Weight=48×96×0.125×0.098=40 lbs

In contrast, a 0.050-inch thick sheet of the same alloy would weigh approximately 16 lbs.

4. Factors Affecting the Weight of Aluminum Sheets

While thickness and alloy are the primary factors influencing the weight, other elements also play a role. These include:

-

Surface Finish: Aluminum sheets with a brushed or anodized finish may weigh slightly more due to the added surface coating.

-

Temperature: Extreme temperatures can cause aluminum to expand or contract slightly, which might affect the weight in specific conditions.

-

Moisture: Although aluminum does not absorb water, it can pick up moisture in humid environments, marginally affecting its overall weight in the short term.

5. Comparison of Different Aluminum Alloys

The table below provides a comparison of common aluminum alloys, their weight per 4x8 sheet, and typical applications:

| Alloy | Thickness (inches) | Weight per Sheet (lbs) | Common Applications |

|---|---|---|---|

| 6061-T6 | 0.125 | 40 | Aerospace, Marine |

| 3003-H14 | 0.125 | 32 | Roofing, Siding |

| 5052-H32 | 0.125 | 36 | Marine, Tanks |

| 6061-T6 | 0.050 | 16 | Structural, Automotive |

6. Case Study: Weight Variations in Real-World Applications

Let's consider the construction of an aluminum-framed structure where two sheets of 4x8 aluminum are used. One sheet is 6061-T6 aluminum (0.125 inches thick), while the other is 3003-H14 aluminum (also 0.125 inches thick). The weight of the frames is crucial for determining how much load they can bear and how easily they can be transported.

In the case of the 6061-T6, the total weight of the two sheets is 80 lbs, compared to 64 lbs for the 3003-H14 aluminum. The additional weight of the 6061-T6 alloy provides more strength, which is beneficial for heavy-duty applications.

7. Frequently Asked Questions (FAQs)

-

What is the lightest aluminum sheet weight for a 4x8 sheet?

-

The lightest aluminum sheet is typically 0.050 inches thick and weighs around 16 lbs.

-

-

How does alloy choice affect the weight of aluminum sheets?

-

Different alloys like 6061-T6 or 5052-H32 have different densities, which means they will weigh more or less depending on the alloy's strength and composition.

-

-

What thickness of aluminum is most commonly used for construction?

-

0.125-inch thick aluminum sheets are the most common in construction and general-purpose applications.

-

-

Is aluminum sheet weight important in the automotive industry?

-

Yes, weight reduction is crucial in the automotive industry to enhance fuel efficiency. Aluminum is favored for its lightweight and high-strength properties.

-

-

Can aluminum sheets be recycled without losing weight?

-

Yes, aluminum is fully recyclable, and the recycling process does not significantly affect its weight or properties.

-

8. Conclusion

Knowing the weight of a 4x8 sheet of aluminum is essential for various applications, whether in construction, automotive, or aerospace industries. Factors like alloy choice, sheet thickness, and finish must be considered when determining the weight of aluminum sheets for specific projects. By using the formulas and comparisons provided, you can accurately calculate the weight and make informed decisions based on the requirements of your project.