Introduction to PPGI Q195

When it comes to modern construction and manufacturing, PPGI Q195 has become a popular choice. Known for its durability and versatility, this coated steel sheet is widely used in roofing, wall cladding, and appliances. Its excellent corrosion resistance and cost-effectiveness make it ideal for various applications. In this article, I’ll explore what makes PPGI Q195 so special, its benefits, and how to select the right product for your needs.

What Is PPGI Q195?

Understanding the Composition and Coating

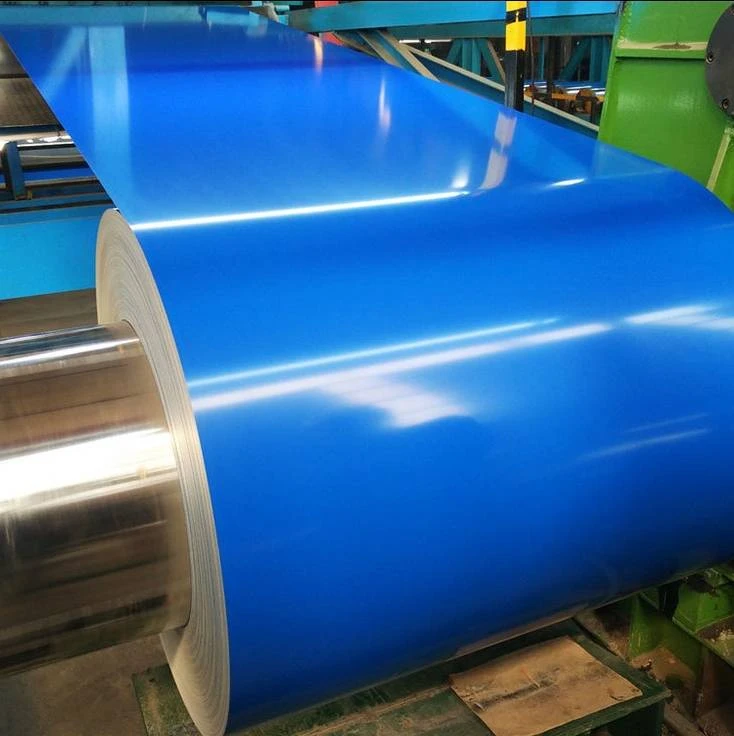

PPGI Q195 stands for Pre-Painted Galvanized Iron with grade Q195 steel. The steel base features a zinc coating for corrosion resistance, while the top layer has a polymer coating, often polyester or PVDF. This combination offers both strength and aesthetic appeal.

Key Properties of PPGI Q195

| Property | Description |

|---|---|

| Thickness Range | 0.12mm - 1.0mm |

| Coating Types | Polyester, PVDF |

| Corrosion Resistance | Excellent |

| Surface Finish | Smooth, glossy |

These features make PPGI Q195 suitable for outdoor applications where weather resistance is crucial.

Related Keywords: Galvanized Steel Sheet, Coated Steel Coil

Advantages of Using PPGI Q195

Excellent Corrosion Resistance

The zinc coating combined with polymer layers protects the steel from rust, even in harsh environments. This durability extends the lifespan of the material significantly.

Cost-Effective Solution

Compared to other coated steels, PPGI Q195 offers a balance of quality and affordability. Its ease of installation reduces labor costs, making it a favorite among builders.

Aesthetic Flexibility

The surface can be painted in various colors and textures, allowing customization. This makes PPGI Q195 perfect for architectural projects requiring visual appeal.

Easy Maintenance

Thanks to its smooth surface and protective coating, cleaning and maintaining PPGI Q195 is straightforward. This reduces long-term upkeep costs.

Related Keywords: Architectural Steel, Protective Coated Steel

Common Applications of PPGI Q195

Roofing and Wall Cladding

Due to its weather resistance, PPGI Q195 is extensively used in roofing sheets and exterior wall panels, especially in regions with high humidity or rainfall.

Household Appliances

The aesthetic appeal and corrosion resistance make it suitable for refrigerator panels, washing machines, and other appliances.

Automotive Industry

Some manufacturers utilize PPGI Q195 for vehicle panels, benefiting from its lightweight and durability.

Agricultural Structures

Barns, greenhouses, and storage sheds often incorporate PPGI Q195 for its resilience and cost efficiency.

Case Study: Durable Farm Shed

In my experience, installing PPGI Q195 panels on a farm shed resulted in zero corrosion after five years, even in a humid climate. This really proves its longevity.

How to Choose the Right PPGI Q195

Step 1: Determine Application Requirements

Identify whether your project needs maximum corrosion resistance, aesthetic appeal, or cost savings.

Step 2: Select Coating Type

Polyester coatings are budget-friendly, while PVDF offers superior weather resistance. Choose based on environmental exposure.

Step 3: Check Thickness Specifications

Ensure the steel thickness matches your structural needs. Thicker sheets provide more strength but may cost more.

Step 4: Verify Surface Finish

Decide on matte or glossy finishes according to your design preferences.

Step 5: Choose a Reliable Supplier

Partner with trusted companies like Shanxi Luokaiwei Steel Company, known for high-quality PPGI Q195 products and excellent service.

Comparing PPGI Q195 with Other Coated Steels

| Feature | PPGI Q195 | PPGL Q235 | Aluminum Composite Panel |

|---|---|---|---|

| Cost | Moderate | Slightly higher | Higher |

| Corrosion Resistance | Excellent | Good | Moderate |

| Weight | Heavier | Similar | Lighter |

| Aesthetic Options | Wide | Limited | Limited |

| Durability | Long-lasting | Good | Moderate |

This table highlights how PPGI Q195 balances cost, durability, and aesthetics, making it a versatile choice.

Common Mistakes to Avoid

⚠️ Ignoring Coating Quality: Not all PPGI Q195 sheets are equal; inferior coatings can lead to early corrosion.

⚠️ Overlooking Environmental Factors: Choose coating types based on exposure conditions. For example, PVDF is better for coastal areas.

⚠️ Choosing the Wrong Thickness: Thinner sheets may not withstand mechanical stresses.

Step-by-Step Installation Guide for PPGI Q195

- Material Inspection: Check for surface defects and ensure product certification.

- Preparation: Clean the surface and prepare the substrate.

- Measurement and Cutting: Measure accurately and cut sheets to size with appropriate tools.

- Fixation: Use suitable fasteners to secure sheets, avoiding over-tightening.

- Sealing and Finishing: Apply sealants if necessary and ensure proper sealing at joints.

Practical Inspection Checklist

- Confirm product certification and coating quality

- Check for surface damages or corrosion signs

- Verify thickness and dimensions match specifications

- Ensure proper surface finish and color consistency

- Conduct a visual inspection before installation

Why Choose Shanxi Luokaiwei Steel Company?

Our company specializes in producing top-grade PPGI Q195 sheets. Here’s what sets us apart:

- Quality Assurance: We use advanced coating technology to ensure durability.

- Competitive Pricing: Our prices are among the best in the industry.

- Reliable Delivery: Timely shipments help your project stay on schedule.

- Technical Support: Our experts provide guidance from selection to installation.

Choosing Shanxi Luokaiwei Steel Company means partnering with a trusted supplier committed to your success. We invite you to contact us for inquiries and quotations—let’s work together to meet your project needs!

In conclusion, PPGI Q195 is a durable, cost-effective, and versatile material suitable for many industries. Its excellent corrosion resistance and aesthetic flexibility make it a top choice for roofing, appliances, and more. Remember to select the right coating, thickness, and supplier to maximize performance. Follow our step-by-step guide and checklists to ensure smooth project execution.