Introduction

Finding reliable 7075-T6 aluminum coil suppliers is crucial for many industries, especially aerospace, automotive, and sporting goods. This alloy is known for its high strength-to-weight ratio and excellent durability. As someone who has sourced this material multiple times, I understand the importance of choosing the right supplier. In this article, I’ll walk you through everything you need to know about 7075-T6 aluminum coil suppliers, including key features, comparison, and how to select the best one.

What Is 7075-T6 Aluminum Coil?

Defining 7075-T6 Aluminum

7075-T6 aluminum is a heat-treated alloy with zinc as its primary alloying element. It offers exceptional strength, comparable to many steels, but with the lightweight advantage of aluminum. This makes it ideal for high-performance applications like aircraft structures, bicycle frames, and military equipment.

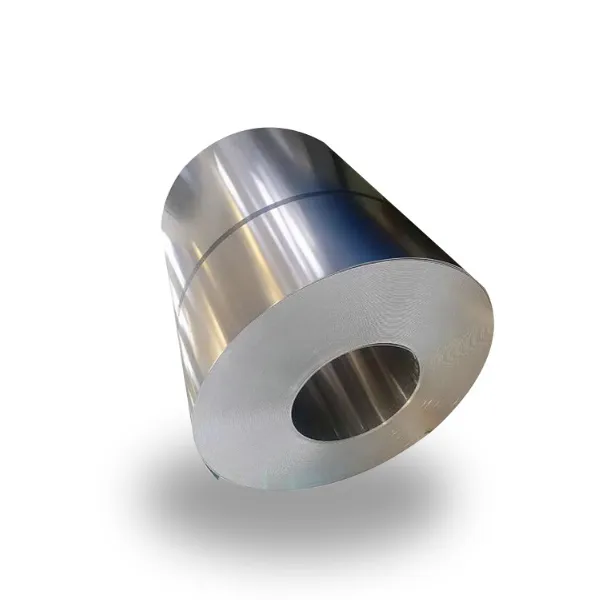

The Significance of Aluminum Coils

Aluminum coils are rolled sheets of aluminum, wound into large rolls for ease of transportation and fabrication. When supplied by 7075-T6 aluminum coil suppliers, these coils are processed to meet strict industry standards, ensuring consistency and quality.

Related Keywords and Their Importance

| Keyword | Explanation | Typical Applications |

|---|---|---|

| Aluminum alloy coils | Rolled sheets of aluminum for fabrication | Construction, transportation |

| Heat-treated aluminum | Treated for enhanced strength | Aerospace, sports equipment |

| High-strength aluminum | Alloy with superior durability | Military, automotive |

(Source: Aluminum Association, 2023)

Why Choose 7075-T6 Aluminum Coil?

Mechanical Properties

7075-T6 aluminum boasts tensile strength around 83,000 psi, making it one of the strongest aluminum alloys. Its high strength combined with good fatigue resistance makes it suitable for demanding environments.

Corrosion Resistance

While 7075-T6 provides excellent mechanical properties, it has moderate corrosion resistance. Proper surface treatment, such as anodizing, is often necessary. This is why choosing 7075-T6 aluminum coil suppliers with quality coatings is essential.

Fabrication & Machinability

This alloy is known for its excellent machinability, especially when supplied as coils. However, it can be more challenging to weld compared to other alloys, so design considerations are important.

Cost Considerations

7075-T6 aluminum is more expensive than other aluminum alloys, but its performance benefits justify the cost for high-end applications. Reliable 7075-T6 aluminum coil suppliers can help you get the best value.

Environmental Suitability

For outdoor or marine environments, additional protective coatings are recommended. Many 7075-T6 aluminum coil suppliers provide coated coils to improve corrosion resistance.

Comparing Different Suppliers: Case Study

In my experience, choosing the right 7075-T6 aluminum coil suppliers can significantly impact project quality and costs. Here’s a comparison table between two hypothetical suppliers:

| Feature | Supplier A | Supplier B |

|---|---|---|

| Certification | ISO 9001, ASTM certified | ISO 9001 certified |

| Price per ton | $3,200 | $3,500 |

| Coil Width Range | 100mm-2000mm | 150mm-1800mm |

| Coating Options | Anodized, painted | Anodized only |

| Delivery Lead Time | 2 weeks | 3 weeks |

This comparison highlights the importance of assessing multiple factors beyond price alone.

How to Select the Best 7075-T6 Aluminum Coil Suppliers

Step-by-Step Guide

- Verify Certifications

Ensure the supplier has ISO 9001, ASTM, or other relevant certifications. - Assess Product Quality

Request material test reports and certificates of conformity. - Check Product Range

Confirm they supply coils in your required dimensions and coatings. - Review Lead Times

Delivery speed can impact your project schedule. - Evaluate Customer Support

Good communication and after-sales service are key.

Common Mistakes to Avoid

⚠️ Overlooking certifications can lead to subpar materials.

⚠️ Ignoring coating options might compromise corrosion resistance.

⚠️ Choosing solely based on price may result in low-quality products.

⚠️ Neglecting supplier reputation can cause delays and quality issues.

Practical Tips for Working with 7075-T6 Aluminum Coil Suppliers

- Always request detailed material test reports before purchasing.

- Clarify your coating and finishing requirements upfront.

- Consider suppliers with experience in your industry.

- Ask about minimum order quantities and discounts for bulk orders.

- Build a good relationship for future projects and support.

Real-Life Experience

During my last project, I needed 7075-T6 aluminum coil for a lightweight drone frame. I sourced from a supplier claiming to be the best. However, after testing, I found the material lacked the promised tensile strength. That experience taught me the importance of verifying certifications and quality documents. Choosing a reputable 7075-T6 aluminum coil supplier saved me from costly rework.

Comparing 7075-T6 Aluminum Coil Suppliers: Key Factors Table

| Factor | Supplier A | Supplier B |

|---|---|---|

| Certification | ISO 9001, ASTM | ISO 9001 |

| Material Quality | Premium, verified test reports | Good, but less transparent |

| Price per kg | $4.50 | $4.80 |

| Coating Options | Anodized, painted | Anodized only |

| Delivery Time | 2 weeks | 3 weeks |

This table demonstrates why choosing the right supplier is more than just about price. Quality and reliability matter.

Practical Operation Steps

- Identify your project specifications

Determine coil dimensions, coating needs, and mechanical properties. - Research and shortlist suppliers

Focus on those with proven certifications and positive reviews. - Request samples and test reports

Verify material quality before bulk purchase. - Compare offers and negotiate

Consider price, lead time, and after-sales support. - Place your order and monitor delivery

Keep communication open to ensure smooth logistics.

Final Practical Checklist

- Confirm the supplier’s certifications (ISO, ASTM).

- Verify material test reports and certificates.

- Check coil dimensions and coating options.

- Review supplier reputation and customer feedback.

- Evaluate lead times and delivery conditions.

- Ensure after-sales support and technical assistance.

- Clarify minimum order quantities and pricing.

- Test samples for mechanical properties.

- Document all agreements and specifications.

- Plan for storage and handling upon delivery.

Why Choose Shanxi Luokaiwei Steel Company?

Our company specializes in 7075-T6 aluminum coil suppliers with a proven track record. We offer:

- Certified, high-quality aluminum coils

- Competitive pricing and flexible delivery options

- Extensive experience serving aerospace, automotive, and industrial sectors

- Dedicated customer support and technical consultation

- Coatings and finishing options tailored to your needs

Partnering with Shanxi Luokaiwei Steel Company ensures you get reliable products and expert service. We’re committed to helping your projects succeed.

Final Thoughts

In conclusion, selecting the right 7075-T6 aluminum coil suppliers is vital for project success. Always prioritize quality, certifications, and supplier reputation. With the right partner, you’ll enjoy durable, high-performance materials that meet your expectations.

Practical Inspection Checklist

- Confirm certifications (ISO, ASTM)

- Review material test reports

- Check coating and finishing options

- Assess supplier reputation and reviews

- Verify delivery timelines

- Confirm minimum order quantities

- Test sample materials

- Confirm pricing and payment terms

- Ensure after-sales support

- Document all specifications and agreements

Ready to source top-quality 7075-T6 aluminum coil? Contact Shanxi Luokaiwei Steel Company today for competitive quotes and expert advice. We look forward to supporting your success!