How to pick the right .024 aluminum coil? (Simple help to choose for what you need)

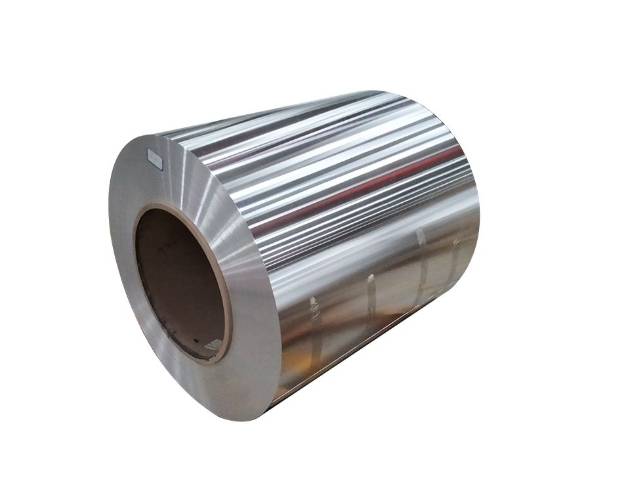

.024 inch aluminum coil refers to aluminum sheet metal that has been rolled into a continuous coil form with a nominal thickness of 0.024 inches (approximately 0.61 millimeters). This thickness offers a balance of light weight, flexibility, and sufficient rigidity for various applications. Common Alloys and Properties Several aluminum alloys are commonly used for .024 […]

How to pick the right .024 aluminum coil? (Simple help to choose for what you need) Read More »