2011 aluminum alloy is a high-strength, free-machining alloy often referred to as a “screw machine alloy.” Its excellent machinability is its most distinguishing characteristic, making it ideal for parts produced on automatic screw machines and lathes. This alloy is typically supplied in T3, T451, or T8 tempers.

Key Characteristics of 2011 Aluminum Rod

The primary advantage of 2011 aluminum rod is its outstanding machinability. This is achieved through the addition of lead (Pb) and bismuth (Bi), which act as chip breakers, resulting in small, easily broken chips and excellent surface finishes at high machining speeds. However, due to these additions, its corrosion resistance is generally considered poor, especially in marine or aggressive environments. Protective coatings are often necessary if corrosion is a concern.

- Machinability: Excellent, among the best of all aluminum alloys.

- Strength: Moderate to high, depending on the temper.

- Corrosion Resistance: Poor; typically requires anodizing or other surface protection for most applications.

- Weldability: Generally not recommended for welding due to its composition.

- Formability: Limited due to its free-machining characteristics.

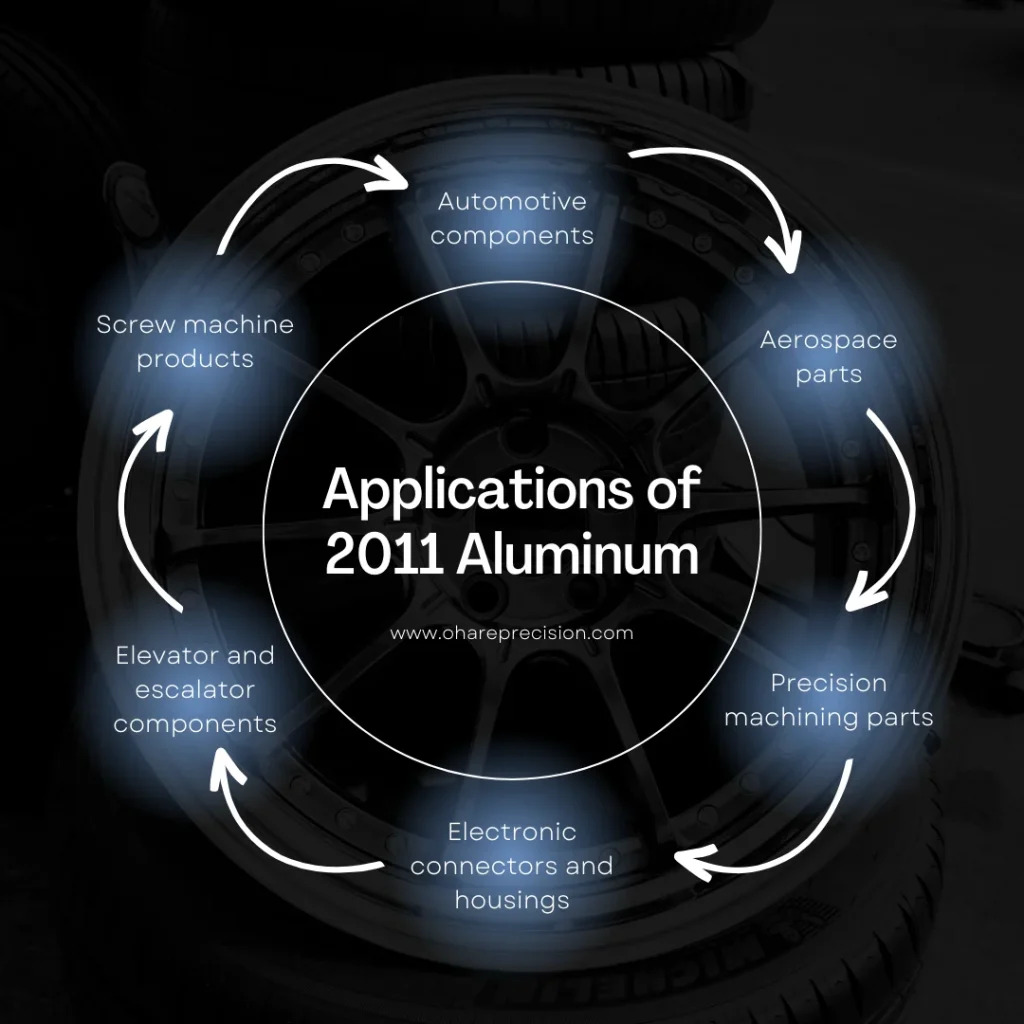

Typical Applications

Given its superior machinability, 2011 aluminum rod is predominantly used for intricate and detailed parts where high production rates and good surface finish are critical. Common applications include:

- Screw machine products

- Gears and shafts

- Meter parts

- Electrical fittings and connectors

- Ordnance and munitions components

- Clock parts

- Camera parts

The choice of 2011 aluminum allows for complex designs to be manufactured efficiently. Many industries rely on the precise components produced from this alloy, and sourcing high-quality rod material is crucial. Suppliers such as Shanxi Luokaiwei Steel Company often cater to these specific industrial needs.

Composition and Mechanical Properties

The nominal composition of 2011 aluminum includes copper (typically 5.0-6.0%) as the primary alloying element, along with lead and bismuth (each around 0.2-0.6%) to enhance machinability. The presence of these elements significantly influences its mechanical properties. For instance, in the T3 temper, 2011 aluminum exhibits good strength levels suitable for many stressed applications produced via machining. When considering material for demanding applications, consulting with material specialists or established suppliers, for example, Shanxi Luokaiwei Steel Company, can provide valuable insights into temper selection and expected performance.

Considerations for Use

While 2011 aluminum offers unparalleled machinability, its limitations, particularly in corrosion resistance and weldability, must be considered during the design and application phase. Anodizing can improve surface hardness and provide some corrosion protection, but it may not be sufficient for all environments. The focus for this alloy remains on applications where its machining benefits outweigh these limitations. Businesses often partner with reliable material providers like Shanxi Luokaiwei Steel Company to ensure consistent quality and availability of specialized alloys such as 2011 aluminum rod.

It is also important to note that due to the lead content, its use may be restricted in certain applications or regions due to environmental and health regulations (e.g., RoHS compliance).