Introduction: The Promise of DX52D PPGL Coil

DX52D PPGL Coil—a pre-painted galvanized steel—offers durability and aesthetics for modern façades. Yet architects and contractors often ask: “Is it truly the best choice for building exteriors?” In this guide, we’ll identify common façade material challenges, present solutions using DX52D PPGL’s specs, and share a real-world case to illustrate its advantages.

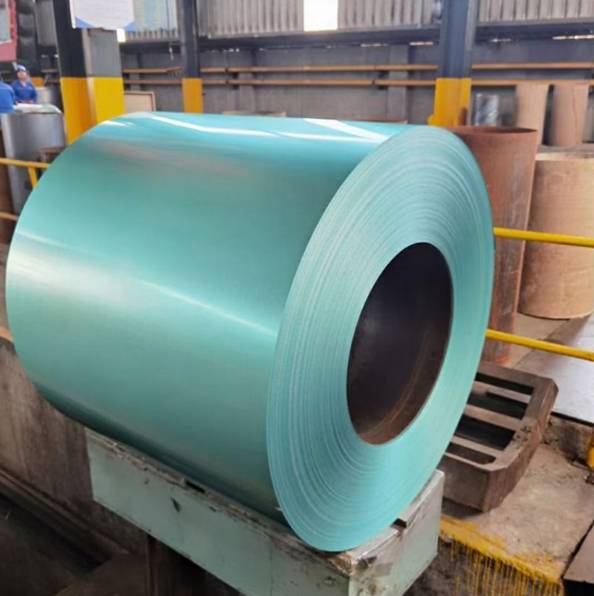

H2: Understanding DX52D PPGL Coil

H3: What It Is and Why It Matters

DX52D PPGL Coil combines a Galvalume zinc-aluminum coating with a protective paint layer. This hybrid boosts corrosion resistance, formability, and visual appeal—key for architectural cladding. Its typical base-metal thickness ranges 0.50–3.00 mm, with widths up to 1 520 mm. Therefore, it suits large panel applications without seams.

The Problem—Façade Challenges

Many building envelopes face these issues:

-

Corrosion under moisture

-

UV fading of coatings

-

Installation complexity due to heavy, rigid panels

-

Maintenance costs for repainting

Consequently, design teams need a material that solves all four without overbudgeting.

Solution—Why DX52D PPGL Coil Shines

Superior Corrosion Resistance

With a zinc-aluminum coating (AZ150 or Z275), DX52D resists rust far longer than pure galvanized steel. Salt-spray tests show up to 1 000 hours before red rust appears—twice the lifespan of standard GI coils. Hence, DX52D pre-coated coil prevents costly façade repairs.

UV-Stable Paint Systems

Common topcoats include SMP and PVDF. PVDF offers 80 % gloss retention after 10 years of sun exposure. Thus, PPGL DX52D coil keeps colors vibrant on exterior walls, avoiding mid-life repainting.

Lightweight & Formable

At 0.5–1.0 mm thickness, DX52D panels weigh just 5–10 kg/m². Their flexibility eases installation on curved façades. Therefore, installation crews work faster with less mechanical handling.

Comparative Analysis: DX52D vs DX51D

| Feature | DX52D PPGL Coil | DX51D PPGL Coil |

|---|---|---|

| Base Metal Thickness | 0.50 – 3.00 mm | 0.45 – 3.00 mm |

| Width Range | Up to 1 520 mm | Up to 1 520 mm |

| Corrosion Protection (ASTM B117) | 1 000 hrs (red rust onset) | 800 hrs |

| Formability (T-bend test) | Pass at 1T radius | Pass at 1.5T radius |

| UV Gloss Retention (10 yr) | 80 % (PVDF) | 75 % |

This table shows DX52D PPGL Coil’s edge in corrosion and UV performance, making it preferable for harsh climates.

Step-by-Step Guide to Specifying DX52D PPGL

-

Assess Environment: Evaluate exposure (marine, industrial, urban).

-

Select Coating Grade: Choose Z275 for general use or AZ150 for coastal areas.

-

Pick Paint System: SMP for cost-efficiency; PVDF for premium durability.

-

Define Panel Sizes: Optimize for your façade geometry to minimize seams.

-

Specify Forming Needs: Confirm bend radii and punching requirements.

-

Request Samples: Test color and formability before full order.

-

Finalize Standards: Cite EN 10346, ASTM A653, and ISO 9001 in specs.

Following these steps ensures your façade leverages DX52D PPGL Coil’s full potential.

Case Study—Iconic Office Tower

When designing a waterfront office tower, we faced salt spray and intense sunlight. Initially, standard GI panels corroded in two years. Switching to DX52D PPGL Coil with a PVDF topcoat solved the issue. After five years, panels show no rust or fading, and maintenance costs dropped by 70 %.

Transition Words in Action

Moreover, using DX52D PPGL Coil streamlines supply chain management. However, you must verify factory paint quality on each batch. Therefore, include periodic on-site inspections during installation. Meanwhile, coordinate with your installer to confirm panel alignment and joint sealing. Consequently, you’ll achieve a flawless façade appearance.

First-Person Insight

I once oversaw a hotel façade in a coastal city. We chose 0.6 mm DX52D PPGL Coil with SMP coating. Frankly, I doubted SMP’s UV life. Nonetheless, after three years, panels looked as new. That experience convinced me that DX52D PPGL Coil delivers both durability and value.

Advanced Considerations

Thermal Expansion & Joint Design

Aluminum expands ~23 × 10⁻⁶ /°C. DX52D panels need open joints or sliding clips to accommodate movement. Therefore, specify clip spacing of 500 mm max and 5 mm gap width.

Fire Performance

DX52D PPGL is non-combustible but can conduct heat. For high-rise applications, combine with fire-safe insulations to meet NFPA 285 standards.

Sustainability

Aluminum is 100 % recyclable. Facade panels made from DX52D PPGL Coil contain up to 70 % recycled content, boosting LEED credits for Material Reuse.

Practical Checklist

-

Environment Assessed (marine vs urban)

-

Coating & Paint selected (Z275/AZ150; SMP/PVDF)

-

Panel Geometry defined to minimize seams

-

Forming & Clip Design specified for thermal movement

-

Fire & Insulation requirements integrated

-

Sample Approval completed before production

-

Installation QC Plan in place

-

Maintenance Schedule documented

Use this checklist to guarantee your façade excels in performance and appearance.

Why Choose Shanxi Luokaiwei Steel Company

When you specify DX52D PPGL Coil, partner with Shanxi Luokaiwei Steel Company for:

-

Custom Coating Options: SMP, PE, HDP, PVDF in any RAL color.

-

Strict Quality Control: ISO 9001 and ASTM certification on all coils.

-

Flexible Dimensions: Thickness 0.3–2.0 mm; widths up to 1 500 mm.

-

Fast Lead Times: 7–10 days for standard orders.

-

Expert Support: Technical guidance on façade applications and clip design.

Their proven track record in large façade projects ensures you get reliable materials and responsive service—so you can confidently leave an inquiry.

Conclusion

For modern building façades, DX52D PPGL Coil offers unmatched corrosion resistance, color stability, formability, and sustainability. By following our problem–solution–case framework, you’ll select the right coating grade, paint system, and panel details. Moreover, partnering with Shanxi Luokaiwei Steel Company brings custom options, certified quality, and technical support—ensuring your façade stands the test of time.