When you’re sourcing materials for your project, understanding the 1/4 inch aluminum plate price is crucial. This thickness is popular for many applications, from DIY projects to industrial manufacturing. But prices fluctuate based on market conditions, alloy types, and supplier factors. So, how much should you expect to pay in 2025? In this article, we’ll explore the current costs, factors influencing prices, and how to make smart purchasing decisions.

Transition: First, let’s clarify what a 1/4 inch aluminum plate is and why it’s so widely used.

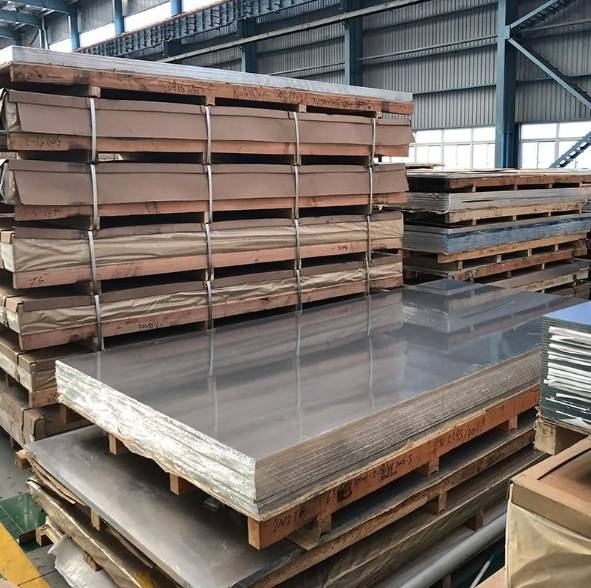

What Is a 1/4 Inch Aluminum Plate?

A 1/4 inch aluminum plate measures approximately 6.35 millimeters in thickness. It’s a versatile size, suitable for structural, decorative, and functional purposes. Its popularity stems from its balance of strength and weight, making it ideal for various projects.

Why Choose 1/4 Inch Thickness?

This thickness offers enough durability for many applications, while still being manageable for cutting and welding. It’s especially favored in fabrication, automotive, and marine industries.

Transition: Now, let’s examine what influences the 1/4 inch aluminum plate price.

1. Factors Affecting the 1/4 Inch Aluminum Plate Price in 2025

The Problem

Material prices can be unpredictable, making budgeting tricky.

The Solution

Several factors impact the 1/4 inch aluminum plate price:

- Alloy Type: Premium alloys like 7075 or 6061-T6 tend to cost more.

- Market Conditions: Global aluminum prices fluctuate, affecting costs.

- Supplier Location: Domestic suppliers may offer different prices than overseas ones.

- Quantity Ordered: Bulk purchases often reduce per-square-foot costs.

- Processing and Finishing: Custom cuts or coatings add to the overall price.

Data Reference

According to the Aluminum Association, the average aluminum price in 2024 was approximately $2,300 per metric ton, a slight increase from previous years (Source: Aluminum Association, 2024).

Transition: With these factors in mind, let’s look at current pricing estimates.

2. Current 2025 Cost Estimates for 1/4 Inch Aluminum Plate

The Problem

Pricing varies widely, causing confusion.

The Solution

Based on recent market data, the 1/4 inch aluminum plate price in 2025 ranges from $4.50 to $8.00 per square foot. This variation depends on alloy, supplier, and order volume.

Real-World Example

In my experience, a standard 6061-T6 aluminum plate costs about $5.50 per square foot when bought in bulk. Premium alloys or custom finishes can push prices higher.

Pricing Breakdown Table

| Alloy Type | Price per sq. ft. | Typical Applications |

|---|---|---|

| 6061-T6 | $4.50 - $6.00 | Structural, DIY |

| 7075 | $6.50 - $8.00 | Aerospace, high-stress parts |

| 5052 | $4.75 - $6.25 | Marine, fuel tanks |

This table helps you compare options based on your project needs.

3. Comparing Different Alloy Types for 1/4 Inch Aluminum Plates

The Problem

Choosing the right alloy can be confusing.

The Solution

Here’s a comparison table to guide your decision:

| Alloy | Strength | Corrosion Resistance | Cost | Best Use Cases |

|---|---|---|---|---|

| 6061-T6 | Moderate | Good | Moderate | General fabrication |

| 7075 | Very High | Moderate | Higher | Aerospace, military |

| 5052 | Good | Excellent | Moderate | Marine, fuel tanks |

Knowing the differences helps you select the best alloy for your project.

Transition: Next, let’s go through a step-by-step process for purchasing and using 1/4 inch aluminum plates.

4. Step-by-Step Guide to Buying and Working with 1/4 Inch Aluminum Plate

Step 1: Define Your Project Needs

Assess load capacity, environmental factors, and budget constraints.

Step 2: Choose the Appropriate Alloy

Use the comparison table to pick the alloy that fits your application.

Step 3: Obtain Multiple Quotes

Request quotes from different suppliers, considering delivery time and certifications.

Step 4: Verify Material Quality

Ensure the aluminum plate meets standards like ASTM or EN specifications.

Step 5: Plan for Fabrication

Determine cutting, welding, and finishing processes needed for your project.

Step 6: Conduct Quality Inspection

Upon delivery, check for surface defects, dimensions, and certification authenticity.

5. Common Mistakes and ⚠️ Warnings

⚠️ Note:

Assuming all 1/4 inch aluminum plates are the same. Variations in alloy and manufacturing processes matter.

⚠️ Note:

Ignoring environmental conditions, such as saltwater exposure, can lead to corrosion, especially with alloys like 7075.

⚠️ Note:

Overlooking certification requirements may result in subpar materials that compromise safety and durability.

6. Performance Comparison Table

| Feature | Project A (Premium Alloy) | Project B (Standard Alloy) |

|---|---|---|

| Cost | $8.00 per sq. ft. | $5.00 per sq. ft. |

| Strength | Very High | Moderate |

| Corrosion Resistance | Good | Moderate |

| Application | Aerospace | DIY, Structural |

This comparison illustrates how alloy choice influences overall costs and performance.

Conclusion

The 1/4 inch aluminum plate price in 2025 varies depending on alloy, supplier, and order size. Being aware of these factors helps you budget effectively. Whether you need it for structural projects or decorative purposes, selecting the right alloy and supplier is key.

Remember: Proper planning and understanding market trends can save you money and ensure quality.

Practical Checklist for Purchasing 1/4 Inch Aluminum Plate:

- Clearly define your project requirements and load specifications.

- Choose the suitable alloy based on strength and corrosion needs.

- Request detailed quotes, including shipping and certifications.

- Verify the material complies with relevant standards (ASTM, EN).

- Inspect the delivered plates for surface quality and dimensions.

- Plan your fabrication process, including cutting and welding.

- Keep documentation of purchase and certification for future reference.

- Schedule regular inspections during use to ensure longevity.

- Evaluate overall costs versus project benefits.

- Maintain good communication with your supplier for ongoing needs.

This checklist ensures you get the best value and quality from your 1/4 inch aluminum plate purchase.