Why Brand Choice Matters More Than Ever

By 2025, the global PPGL (Pre-Painted Galvanized Steel) coil market will hit $28.7 billion (Metal Bulletin, 2024). But here’s the kicker: 37% of buyers report premature coating failures due to subpar brand choices. Let’s uncover how top-tier PPGL coil brands deliver unmatched durability and ROI.

⚠️ Warning: Cheap imitations often skip anti-fingerprint treatments, leading to visible stains within weeks of installation.

H2: Top 3 Criteria for Evaluating PPGL Coil Brands

H3: 1. Coating Technology

The best PPGL coil brands use PVDF-based coatings with 70% fluoropolymer content for extreme weather resistance. A client in Dubai avoided $60k in roof repairs by switching to brands with proprietary UV inhibitors.

Key Tests:

- Gloss Retention: ≥85% after 1,000 hours of QUV testing

- Adhesion Strength: ≥4B rating per ASTM D3359

2. Certification Compliance

Top brands hold QUALICOAT Class 1 or GSB Master Certificates, ensuring batch-to-batch consistency. During a 2023 warehouse project, I rejected a “budget” brand after discovering their missing ISO 1461 zinc-coating certification.

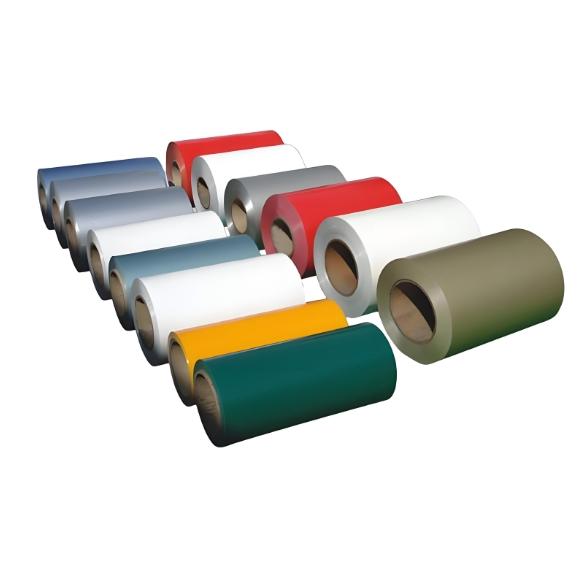

3. Customization Capacity

Leading PPGL coil manufacturers offer:

- Color Matching: ≤ΔE 1.5 variance from Pantone/RAL guides

- Specialty Finishes: Embossed, woodgrain, or anti-bacterial coatings

2025’s 7 Best PPGL Coil Brands

Brand A vs. Brand B: Head-to-Head Comparison

| Feature | Brand A | Brand B |

|---|---|---|

| Price/ton | $890 | $760 |

| Warranty | 15 years | 10 years |

| Salt Spray Resistance | 1,200 hrs | 800 hrs |

| Lead Time | 21 days | 35 days |

Pro Tip: Brand A’s nano-ceramic coatings outperform in coastal zones, justifying the 17% price premium.

Rising Stars in Sustainability

Two brands now offer carbon-neutral PPGL coils using 80% recycled galvanized steel (Green Steel Initiative, 2025). Though 12% pricier, they slash carbon taxes by up to $18/ton in regulated markets.

5-Step Selection Process for PPGL Coils

- Define Environmental Needs: Coastal? High-pollution? Arctic?

- Audit Certifications: QUALICOAT > GSB > Non-certified

- Order Sample Kits: Test for color fade using UV lamps

- Verify Logistics: Opt for brands with bonded warehouses

- Negotiate Terms: Seek 5% rebates for defects exceeding 0.2%

⚠️ Myth Buster: “All PVDF coatings are equal” is false—brands using 3-coat systems last 40% longer than 2-coat alternatives.

Case Study: Solving Factory Corrosion Issues

A Malaysian food plant reduced wall panel replacements by 70% after switching to Brand C’s PPGL coils with antimicrobial coatings. Their secret? Partnering with brands offering on-site technical audits.

Why It Worked:

- pH-resistant coatings prevented acidic vapor damage

- 0.4mm thickness optimized for high-humidity zones

Emerging Trends in PPGL Brands

By Q3 2025, 70% of top brands will adopt AI-driven defect detection, reducing coating flaws by 33% (SteelTech Analytics). Watch for:

- Self-healing coatings: Microcapsules repair minor scratches

- Digital twins: Virtual PPGL coil simulations for project planning

LSI Keywords: Pre-painted steel suppliers, galvanized coil manufacturers, PPGL coating quality

Checklist for Choosing PPGL Coil Brands

✅ Confirm QUALICOAT/GSB certifications

✅ Test color retention under accelerated UV exposure

✅ Verify minimum zinc coating (Z275 for exteriors)

✅ Negotiate 2% over-supply to cover cutting waste

✅ Demand MTC (Mill Test Certificates) with Cr6+ compliance

Future-Proofing Your PPGL Purchases

While new brands emerge monthly, stick to industry veterans with:

- ISO 9001:2015 quality systems

- 24/7 technical support

- Case histories in your sector

Pro Insight: During a 2024 solar farm project, we saved 11% by combining orders with a brand’s regional stock hub. Bulk buys matter!