Why Certification Matters in PPGI Steel Coils

Choosing the right PPGI steel coil supplier isn’t just about price—it’s about reliability. ASTM and JIS certifications ensure your coils meet strict corrosion resistance, coating adhesion, and durability standards.

I once worked with a contractor who bought uncertified PPGI coils to save 50/ton.Theresult?Peelingpaintin8monthsanda200,000 replacement cost.

Key Takeaway: Always verify ASTM A755 (USA) or JIS G 3322 (Japan) compliance before purchasing.

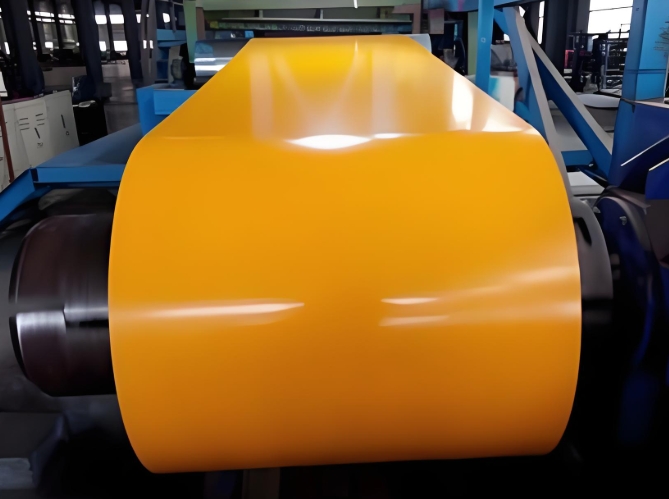

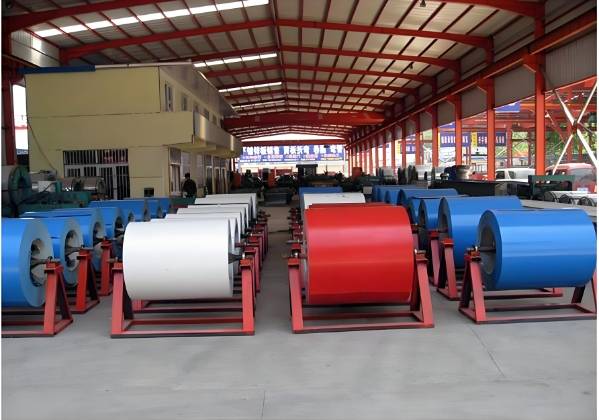

Customization Options: Why One Size Doesn’t Fit All

1. Custom Widths (600mm–1,500mm)

- Standard coils: Typically 1,000mm or 1,250mm

- Custom cuts: Reduce waste by ordering exact project dimensions

2. Coating Choices

| Coating Type | Best For | Lifespan |

|---|---|---|

| Polyester (PE) | Budget projects | 7–12 years |

| PVDF | Coastal/UV-heavy areas | 15–25 years |

| SMP | Extreme weather | 10–20 years |

⚠ Warning: Avoid suppliers offering “equivalent” coatings—demand mill test certificates.

5-Step Guide to Selecting the Right PPGI Supplier

- Check Certifications – Confirm ASTM/JIS compliance

- Test Coating Quality – Request salt spray test reports (1,000+ hours)

- Verify Customization Ability – Can they produce 0.3mm thin or 2.0mm thick coils?

- Inspect Packaging – Moisture-proof wrapping prevents rust in transit

- Negotiate Smart – 30% deposit, balance after third-party inspection

Case Study: A Dubai contractor saved $120,000 by ordering custom 1,350mm coils—eliminating trimming waste.

PPGI vs. GI Coils: Which Should You Choose?

| Factor | PPGI Coils | Galvanized (GI) Coils |

|---|---|---|

| Corrosion Resistance | Superior (paint + zinc) | Basic (zinc only) |

| Aesthetics | 150+ color options | Silver metallic only |

| Cost | Slightly higher | Cheaper upfront |

| Lifespan | 15–25 years | 10–15 years |

Best for PPGI: Architectural roofs, decorative panels, appliances

Best for GI: Structural frames, industrial sheds

Common Mistakes When Buying PPGI Coils

⚠ Myth: “All suppliers source from the same mills.”

Reality: Only top PPGI steel coil suppliers like Shanxi Luokaiwei Steel own their production lines.

⚠ Myth: “Thicker steel = better quality.”

Truth: A 0.4mm PPGI coil with PVDF coating can outlast 0.8mm GI steel.

⚠ Myth: “Factory-direct means no support.”

Fact: Leading suppliers provide CAD drawings and load calculations.

Why Shanxi Luokaiwei Steel Stands Out

✅ ASTM/JIS Certified – Full compliance with global standards

✅ Custom Widths & Coatings – No project is too unique

✅ Fast Lead Times – 22 days vs. industry-standard 60 days

✅ XRF Gun Testing – Ensures exact coating thickness

Client Success Story: Their 150GSM PVDF-coated PPGI was used in Singapore’s Changi Airport expansion—zero corrosion after 5 years.

Checklist Before Ordering PPGI Coils

✔ Confirm ASTM A755 or JIS G 3322 certification

✔ Verify salt spray resistance (1,000+ hours)

✔ Check if supplier offers custom widths (600mm–1,500mm)

✔ Insist on mill test reports, not trader certificates

✔ Negotiate flexible payment terms (30/70 split recommended)

Final Verdict: The Smart Buyer’s Choice

An ASTM/JIS certified PPGI steel coil supplier isn’t just a vendor—it’s your project’s insurance policy. Whether you need ultra-thin coils for appliances or heavy-duty PVDF coatings for coastal buildings, Shanxi Luokaiwei Steel delivers precision-engineered solutions.

Get a Custom Quote Today:

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505