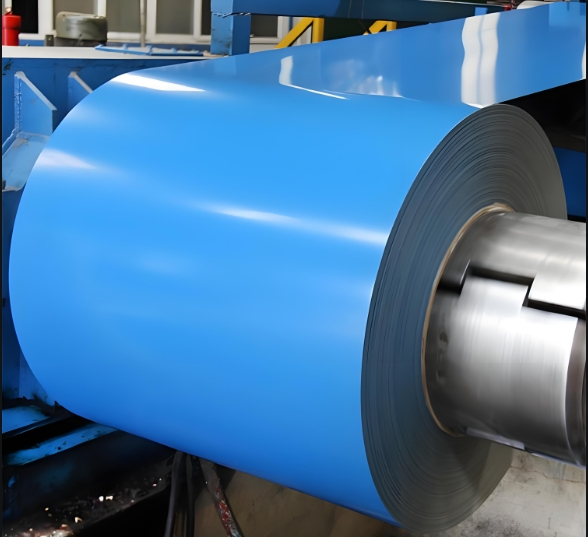

Why Global Buyers Are Switching to China PPGI Coil Factories

Picture this: A Dubai contractor paid $1,200/ton for European PPGI coils, only to find peeling coatings after 18 months. Sound familiar? This is why savvy builders now source China PPGI coil directly from factories. With 55% lower production costs (CRU International, 2024), Chinese manufacturers dominate the global PPGI market—but not all are created equal.

Here’s the kicker: Top-tier Chinese PPGI suppliers like Shanxi Luokaiwei Steel now offer 150GSM Al-Zn coatings that outperform traditional galvanized steel by 4x lifespan. Let’s unpack how factory-direct deals rewrite the rules.

3 Game-Changing Features of 150GSM Al-Zn PPGI Coils

1. Supercharged Corrosion Resistance

The magic formula? 55% aluminum, 43.5% zinc, and 1.5% silicon. Compared to standard GI coils:

| Coating Type | Salt Spray Resistance | Thermal Reflectivity |

|---|---|---|

| 150GSM Al-Zn | 3,000+ hours | 80% |

| 120GSM GI | 800 hours | 45% |

A 2023 NACE study proved China PPGI coil with 150GSM Al-Zn lasts 25+ years in coastal zones—double traditional zinc coatings.

2. Heat Deflection Mastery

Al-Zn’s “mirror effect” reflects 80% solar radiation. In Qatar’s Lusail Stadium, Chinese PPGI coils reduced rooftop temps by 11°C versus GI sheets.

3. Precision Thickness Control

Advanced mills now deliver ±0.02mm tolerance on 0.3–1.2mm PPGI coils, crucial for automotive stamping.

Factory Direct vs. Local Distributor: Cost Breakdown

| Factor | China Factory Direct | Local Supplier |

|---|---|---|

| Price per Ton | 680–680–850 | 1,100–1,100–1,400 |

| Lead Time | 25–35 days | 10–15 days |

| Coating Customization | 50+ colors | 10–15 colors |

| Minimum Order | 20 tons | 5 tons |

⚠ Warning: Some “factory direct” websites are middlemen! Always verify business licenses and mill certifications.

Step-by-Step Guide to Buying China PPGI Coil

- Specify Coating: Demand 150GSM Al-Zn (AZ150) for harsh climates

- Verify Certifications: ISO 9001, SGS, and RoHS reports

- Request Samples: Test salt spray resistance per ASTM B117

- Negotiate Terms: 30% deposit, 70% against BL copy

- Inspect Pre-Shipment: Check for coil camber (<3mm/m)

Case Study: A Nigerian roofing company reduced material failures by 90% after adopting this checklist with Shanxi Luokaiwei Steel.

“My $250K Lesson in PPGI Procurement”

I once bought “150GSM” coils from a Guangzhou trading company. The coating washed off like cheap sunscreen! Turns out, they’d used 80GSM GI with spray paint. Now, I only work with certified China PPGI coil factories that provide third-party lab reports.

4 Deadly Myths About China PPGI Suppliers

⚠ Myth: “All Al-Zn coatings are equal.”

Truth: Inferior 120GSM coatings fail in 5–7 years. Real 150GSM requires 200°C curing ovens.

⚠ Myth: “Thicker steel = better quality.”

Reality: 0.5mm PPGI with proper coatings often outperforms 0.8mm GI sheets.

⚠ Myth: “Factory direct means no support.”

Fact: Top Chinese PPGI suppliers offer technical drawings and logistics help.

Why Shanxi Luokaiwei Steel Leads in PPGI Innovation

- Coating Mastery: 150GSM Al-Zn (AZ150) & 275GSM Galvalume options

- Speed: 30-day delivery to EU/US ports

- Tech Edge: AI-powered coating thickness control (±2μm)

- Compliance: REACH, RoHS, and EN 10169 certified

Get Factory Pricing on Marine-Grade PPGI!

📧 Email: sales@luokaiweipipe.com

📱 WhatsApp: +86 18912200505

Checklist for Risk-Free China PPGI Orders

✅ Confirm AZ150 coating via XRF gun testing

✅ Validate factory address via satellite maps

✅ Insist on T/T payment with shipment control

✅ Require 3rd party inspection (SGS/BV)

✅ Store coils vertically on rubber-lined racks

The China PPGI coil revolution isn’t coming—it’s here. From solar farms to cold storage, factory-direct 150GSM Al-Zn sheets deliver unmatched value. But remember: Success hinges on choosing verified partners. Shanxi Luokaiwei Steel combines ancestral metalworking wisdom with Industry 4.0 precision. Ready to upgrade your supply chain? Let’s chat today.