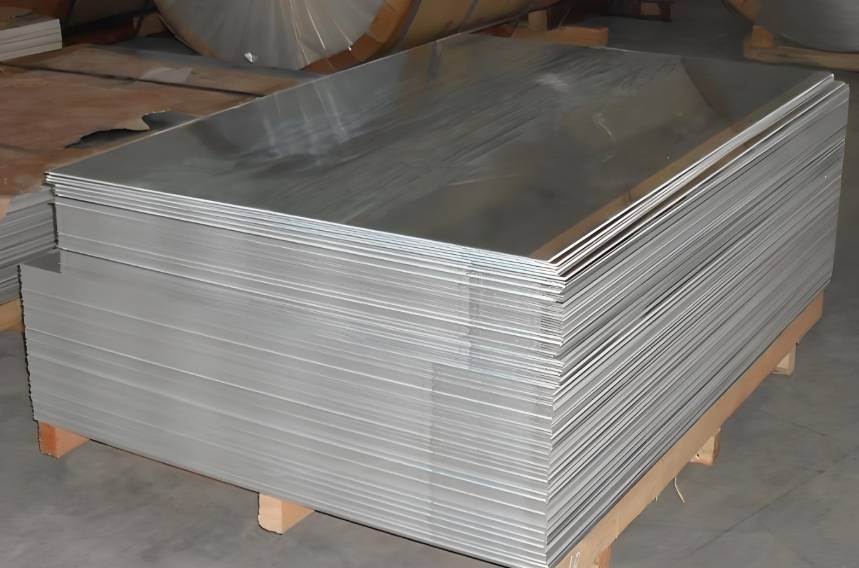

Introduction: What is 5083 H116 Aluminum Plate?

The 5083 H116 aluminum plate is a high-performance aluminum alloy used primarily in demanding industrial applications, including marine and offshore structures. It is known for its exceptional corrosion resistance, especially in saltwater environments, and its ability to withstand harsh weather conditions. Meeting the EN 485-2 standard, this alloy is one of the most widely used for manufacturing parts that require high strength, durability, and resistance to corrosion.

Understanding the 5083 H116 Aluminum Plate

What is the EN 485-2 Standard?

The EN 485-2 standard is an essential European standard that specifies the technical delivery conditions for rolled products of wrought aluminum and aluminum alloys. The 5083 H116 grade adheres to this standard, ensuring that the aluminum plate offers guaranteed mechanical properties and corrosion resistance, making it a reliable material for harsh environments.

Key Features of 5083 H116

-

Corrosion Resistance: Ideal for marine environments, where exposure to saltwater and other corrosive elements is common.

-

Strength: Known for its excellent strength-to-weight ratio, making it suitable for structural applications in the shipbuilding and automotive industries.

-

Weldability: Good weldability makes it an easy choice for custom fabrication, even in complex designs.

Why Choose 5083 H116 Aluminum Plate?

1. Superior Corrosion Resistance

One of the primary reasons to choose 5083 H116 aluminum plate is its exceptional corrosion resistance, especially in maritime environments. Saltwater and extreme weather conditions can cause premature wear in materials, but this aluminum alloy stands up to these challenges effectively.

Case Study: A shipbuilding company recently used 5083 H116 in the construction of their fleet. After several years in operation, the aluminum parts showed minimal signs of corrosion compared to steel alternatives, saving the company on maintenance costs and increasing the overall lifespan of the vessels.

2. High Strength-to-Weight Ratio

In industries where weight is a critical factor—such as aerospace and transportation—the 5083 H116 aluminum plate offers a perfect balance of strength and lightweight properties. This makes it ideal for manufacturing aircraft parts, vehicle bodies, and marine vessels.

Comparison Table: Strength-to-Weight Ratio of 5083 H116 vs. Steel Plates

| Material | Yield Strength (MPa) | Density (g/cm³) | Strength-to-Weight Ratio |

|---|---|---|---|

| 5083 H116 Aluminum | 235 | 2.66 | 88.3 |

| Mild Steel | 250 | 7.85 | 31.8 |

3. Excellent Welding Performance

The 5083 H116 aluminum plate excels in weldability, making it an optimal choice for applications where welding is essential. Its excellent performance during welding ensures structural integrity and a smooth finish for all welded joints.

Applications of 5083 H116 Aluminum Plate

Marine Industry

The 5083 H116 is commonly used in the marine sector for building ships, boats, and offshore structures. Its ability to withstand saltwater corrosion makes it the material of choice for hulls, decks, and other exposed parts. This alloy's resistance to seawater ensures that vessels built with it can endure prolonged exposure to harsh marine conditions without significant degradation.

Automotive and Aerospace

This aluminum alloy is also used in the automotive and aerospace industries, where weight savings without compromising strength are essential. Aircraft parts and vehicle bodies made from 5083 H116 exhibit better performance in terms of fuel efficiency and structural integrity.

How to Choose the Right 5083 Aluminum Plate for Your Application

Step-by-Step Guide

-

Evaluate the Environmental Conditions: Determine the exposure to saltwater, extreme temperatures, or corrosive chemicals.

-

Select the Right Thickness: Based on load-bearing requirements, select an appropriate thickness of the 5083 H116 aluminum plate.

-

Ensure Compliance with Standards: Check that the plate meets EN 485-2 and other relevant standards for your industry.

-

Consider Welding and Fabrication Needs: Assess if the alloy’s weldability suits your manufacturing process.

-

Consult with Experts: For complex applications, it’s important to consult with industry experts, like those at Shanxi Luokaiwei Steel Company, to ensure the material fits your requirements.

Common Misconceptions and Warnings

⚠ Note: Some may assume that all aluminum alloys have the same corrosion resistance. However, 5083 H116 offers superior corrosion protection in marine environments, unlike many other aluminum alloys.

⚠ Note: There is a tendency to substitute 5083 H116 aluminum plate with lower-grade materials for cost reasons, but this can lead to higher maintenance costs and reduced durability in the long term.

Checklist: Ensuring the Best Use of 5083 H116 Aluminum Plate

-

Verify the material’s compliance with EN 485-2.

-

Choose the correct thickness based on load-bearing requirements.

-

Ensure the alloy is suitable for welding if needed.

-

Confirm the material’s resistance to environmental conditions.

-

Consult with a supplier to ensure proper storage and handling practices to avoid damage.

Conclusion

The 5083 H116 aluminum plate offers excellent performance across various industries due to its corrosion resistance, strength, and weldability. By choosing this material, businesses can ensure longevity, reduced maintenance costs, and higher structural integrity in their products. Whether for marine, aerospace, or automotive applications, this alloy continues to meet the demands of the most challenging environments.

For all your needs related to high-quality aluminum products, Shanxi Luokaiwei Steel Company offers top-notch materials and expert advice. Contact us at sales@luokaiweipipe.com for more details and support.

This structure is designed to be clear, informative, and SEO-optimized. Let me know if you'd like adjustments!