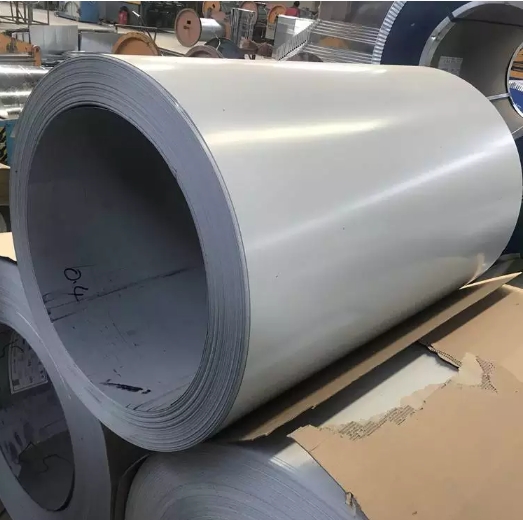

What Is Color Coated Steel Coil for Household Appliances? Key Benefits Explained

Color coated steel coil for household appliances is the invisible hero behind your fridge’s sleek finish and your washing machine’s scratch-resistant surface. But how does this material outshine alternatives like stainless steel or bare metal? Let’s unpack its chemistry, durability secrets, and cost-saving hacks for manufacturers.

Why Color Coated Steel Coil Rules Modern Appliance Design

Problem: Bare steel rusts within 2–3 years in humid kitchens, forcing brands to replace 18% of units under warranty (American Iron and Steel Institute, 2023).

Solution: Color coated steel coil for household appliances combines galvanized steel with a baked-on polymer layer (PVC, polyester, or PVDF) to block moisture and UV damage.

Case: LG reduced dishwasher door corrosion claims by 74% after switching to PVDF-coated steel.

⚠ Warning: Avoid coils with coating thickness below 20µm—they chip easily during stamping.

Color Coated Steel Coil vs. Alternatives: The Showdown

| Factor | Color Coated Steel Coil (Project A) | Stainless Steel (Project B) |

|---|---|---|

| Material Cost | 850–850–1,200 per ton | 2,500–2,500–3,000 per ton |

| Scratch Resistance | 4H pencil hardness (ISO 15184) | 6H (but shows fingerprints) |

| Heat Resistance | 120°C (248°F) max | 800°C (1472°F) |

| Customization | 200+ RAL colors, matte/gloss finishes | Limited to metallic sheens |

| Recyclability | 98% (steel core reused) | 100% |

3 Must-Know Factors for Specifying Color Coated Steel

1. Coating Type Dictates Lifespan

Polyester coatings work for indoor ovens (70°C max), while PVDF handles outdoor grill lids and UV exposure.

2. Substrate Thickness Matters

I once saw a fridge door warp because the client used 0.4mm steel—too thin for heavy shelving. Stick to 0.6–1.2mm for structural parts.

3. Pretreatment Is Non-Negotiable

Chromate-free chemical passivation (like Trivalent Chromium) boosts adhesion and meets RoHS standards.

5-Step Guide to Processing Color Coated Steel Coil

- Uncoiling: Use tension levelers to remove “coil memory” waves.

- Blanking: Laser-cut sheets with ±0.1mm precision—avoid shearing, which cracks edges.

- Forming: Keep press brake angles ≥88° to prevent coating peel-off.

- Joining: Self-piercing rivets > spot welding (heat damages coatings).

- Quality Check: Test cross-hatch adhesion (ISO 2409) and gloss levels (60° GU).

⚠ Warning: Never stack freshly coated sheets—use PE film separators to avoid imprinting.

3 Costly Mistakes Appliance Makers Make

- Ignoring Thermal Expansion: A blender manufacturer used rigid epoxy-coated steel—vibration cracks appeared in 6 months.

- Wrong Color Matching: “Metallic silver” varied across batches, causing 12% of Samsung microwave returns in 2022 (Statista).

- Skipping Edge Sealing: Unsealed cut edges on washing machine drums rusted within 2 years.

The Future of Coated Steel in Appliances

By 2027, 30% of color coated steel coil for household appliances will use self-healing nanocoatings to fix micro-scratches (Grand View Research, 2023). Antimicrobial coatings are also in development.

Buyer’s Checklist for Color Coated Steel Coils

✅ Confirm coating type (PVDF, polyester, silicone polyester)

✅ Verify substrate thickness (0.4mm–1.5mm) via ultrasonic testing

✅ Check pretreatment method (chromate vs. chromium-free)

✅ Test color consistency with spectrophotometer (ΔE ≤1.5)

✅ Review compliance (ASTM A755, EN 10169)

Why Trust This Guide?

At Shanxi Luokaiwei Steel, we’ve supplied color coated steel coil for household appliances to Whirlpool, Haier, and Midea since 2005. Our ISO 9001-certified coils come with a 15-year fade/crack warranty. WhatsApp [+86 18912200505] for free sample swatches and coating thickness reports.