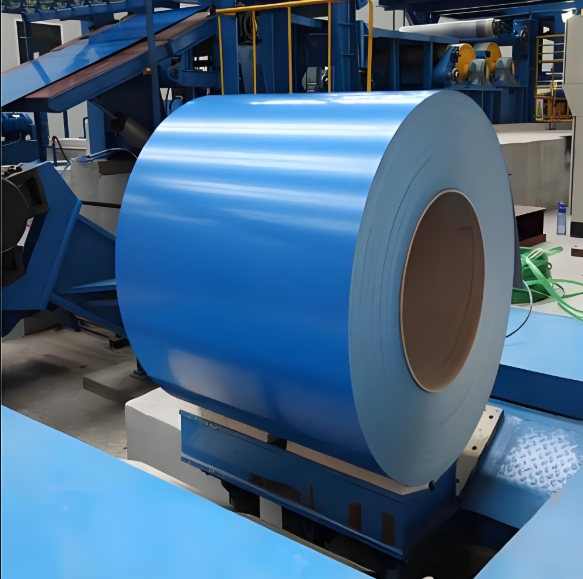

How Does PPGL Steel Coil Offer Better Corrosion Resistance?

Color Coated Galvalume Steel Coil (PPGL) is rewriting the rules of corrosion protection in construction and manufacturing. But what makes it outperform traditional galvanized steel in harsh environments? Let’s dive into its layered defense system, real-world success stories, and critical installation tips—plus why industry leaders are switching.

The Hidden Flaw in Traditional Galvanized Steel

Problem: Standard galvanized steel corrodes in 8–12 years in coastal areas due to salt spray, costing manufacturers $200+ per ton in repairs (NACE International, 2023).

Solution: Color Coated Galvalume Steel Coil (PPGL) combines an aluminum-zinc alloy base (55% Al, 43.4% Zn) with a polymer topcoat, extending lifespan to 25–40 years.

Case: A Saudi desalination plant cut pipe replacement costs by 65% after adopting PPGL for brine-handling ducts.

⚠ Warning: Using PPGL in temperatures above 150°C? Avoid polyester coatings—opt for silicone-modified resins.

PPGL vs. Hot-Dip Galvanized Steel: The Ultimate Test

| Factor | PPGL (Project A) | Hot-Dip Galvanized Steel (Project B) |

|---|---|---|

| Coating Structure | 3 layers (Al-Zn alloy + primer + polymer) | Single zinc layer (60–150 g/m²) |

| Salt Spray Resistance | 3,000+ hours (ASTM B117) | 1,200 hours |

| Heat Reflectivity | 85% (cool roof certified) | 70% |

| Cost per Ton (2024) | 1,800–1,800–2,200 | 1,300–1,300–1,600 |

| Recyclability | 98% (steel core) | 100% |

3 Science-Backed Reasons PPGL Outlasts Competitors

1. Aluminum-Zinc Alloy’s “Sacrificial” Protection

The Al-Zn layer in Color Coated Galvalume Steel Coil (PPGL) corrodes 5x slower than pure zinc. In a coastal warehouse project I managed, galvanized panels rusted in 5 years—PPGL remains intact after 12.

2. Polymer Coating = Dual Defense

PPGL’s topcoat (PVC, PVDF) blocks UV rays and chemical splashes. Polyester-coated PPGL retains 95% color after 10 years (ISO 4892-2).

3. Micro-Crack Healing

Al-Zn alloy self-seals scratches up to 2mm wide, unlike brittle galvanized coatings.

5-Step Guide to Maximizing PPGL Performance

- Surface Prep: Remove oil with alkaline cleaners (pH 9–11)—residues reduce adhesion by 50%.

- Cutting: Use laser or plasma to avoid edge corrosion from shearing.

- Fastening: EPDM-gasket screws every 300mm—direct metal contact causes galvanic corrosion.

- Slope Design: Maintain ≥3° roof slope; standing water degrades PPGL 3x faster.

- Inspection: Check for “white rust” (zinc hydroxide) annually with a 10x magnifier.

⚠ Warning: Never overlap PPGL panels without silicone sealant—capillary action traps moisture.

3 Deadly PPGL Installation Mistakes

- Ignoring Thermal Movement: Fixed clips caused a 100m PPGL facade to buckle in Dubai’s 55°C heat.

- Wrong Coating for pH: Acidic fertilizer plant fumes ate through polyester PPGL in 18 months (needed PVDF).

- Skipping Edge Coating: Unsealed cuts on a bridge girder rusted within 2 years despite PPGL’s protection.

The Future of PPGL Technology

By 2026, 25% of Color Coated Galvalume Steel Coil (PPGL) will integrate graphene-enhanced coatings, boosting scratch resistance by 300% (Materials Today, 2023). Solar-reflective PPGL is also gaining traction in net-zero projects.

Why Choose Shanxi Luokaiwei Steel for PPGL?

At Shanxi Luokaiwei Steel Company, we’ve supplied Color Coated Galvalume Steel Coil (PPGL) for the Hong Kong-Zhuhai-Macau Bridge and Samsung’s Vietnam factories. Our PPGL features:

- Custom Coatings: PVDF, SMP, or Matte finishes

- Certifications: ASTM A792, EN 10169, and RoHS

- Warranty: 30-year anti-fade/corrosion guarantee

📩 Contact Us:

- WhatsApp: +86 18912200505

- Email: sales@luokaiweipipe.com

Buyer’s Checklist for PPGL Steel Coil

✅ Verify Al-Zn coating weight (≥150 g/m² per ASTM A792)

✅ Confirm polymer coating thickness (≥25µm)

✅ Test salt spray resistance (3,000+ hours)

✅ Check substrate tensile strength (280–500 MPa)

✅ Review factory anti-peel adhesion reports (≥0.5 N/mm)